Slate brings unique beauty to flooring, walls, and outdoor features, with rich color variations and layered textures formed over millions of years. Its cleft surfaces offer both visual and tactile appeal, making it a favorite among designers and stone fabricators.

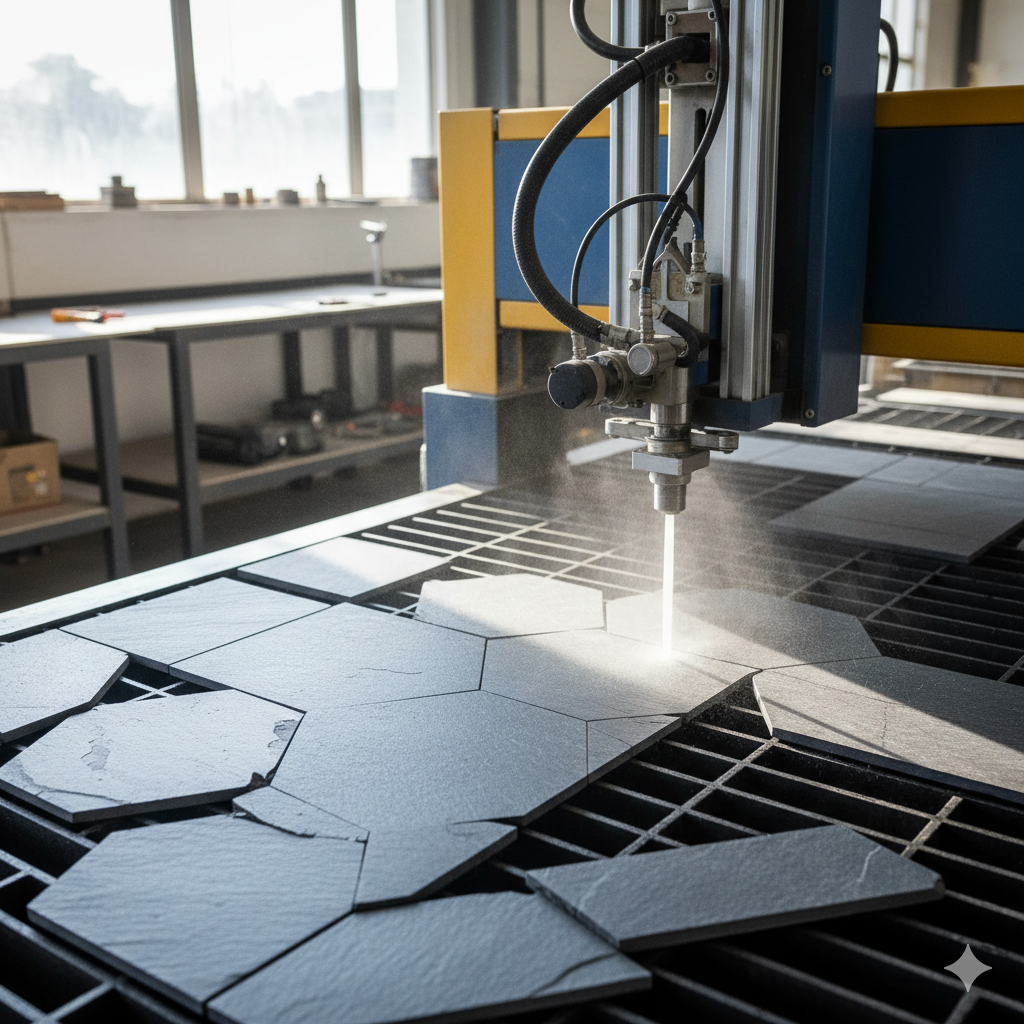

Traditional cutting can damage slate’s delicate layers, limiting design possibilities. Waterjet cutting technology provides precision and control, enabling intricate patterns and accurate dimensions without compromising the stone’s integrity.

The result is flawless layouts that maintain slate’s natural character. Waterjet cutting streamlines installation, supports creative designs, and preserves the material’s inherent elegance, ensuring each project highlights the timeless beauty of slate.

Understanding Slate’s Layered Structure

Slate is a metamorphic rock shaped by the compression of clay and volcanic ash, creating its characteristic layered texture and subtle color variations. Each layer exhibits unique density and structural qualities, contributing to slate’s natural beauty and distinct character.

Waterjet cutting interacts gently with these layers, following precise digital paths that preserve their integrity. This approach ensures clean, accurate cuts while highlighting the material’s natural patterns and textures.

By maintaining the strength and appearance of each layer, waterjet cutting supports reliable fabrication and professional outcomes. Slate inlays and designs retain their visual depth and structural stability, enhancing the overall aesthetic of the finished space.

Advantages of Waterjet Cutting for Slate

Layer Integrity Preservation

Waterjet cutting removes material through a high-velocity water stream combined with fine garnet abrasive. The process avoids mechanical force, allowing layers to separate cleanly as the cut progresses. This precision prevents stress-induced fractures and maintains the uniformity of the slate, making complex designs achievable without compromising material strength.

Maintaining Natural Surface Texture

The cleft surface of slate remains intact during waterjet cutting. Edges retain their natural feel and appearance, supporting design intentions where authenticity matters. The process ensures that even detailed cuts or intricate curves keep the organic quality of the stone, enhancing the overall visual impact of floors, walls, and countertops.

Complex Shapes and Custom Designs

Curved edges, radii, and decorative inlays become manageable with waterjet cutting. The technique allows consistent precision across various slate thicknesses and patterns, supporting creative designs in landscaping, interior spaces, and architectural features. This capability enables designers and fabricators to expand their creative palette while maintaining material integrity.

Applications That Benefit from Waterjet Precision

Outdoor Kitchen and Bar Countertops

Slate countertops require precise cutouts for sinks, cooktops, and edges. Waterjet cutting ensures clean openings, preserving edge structure and durability in moisture-exposed areas.

Custom Shower and Wet Room Installations

Shower walls and wet room floors often have intricate drain and niche designs. Waterjet cutting achieves precise edges that maintain the slate’s natural layers, supporting long-lasting installations and preventing water-related degradation.

Decorative Floor Borders and Medallions

Floor designs that incorporate geometric patterns or logos require accuracy. Waterjet cutting produces uniform pieces, allowing for seamless pattern execution even with naturally varied slate layers.

Curved Walkways and Patio Edging

Curved borders and organic landscaping designs benefit from waterjet precision. Smooth radiused pieces follow the intended design, complementing natural surroundings while preserving slate’s layered structure.

Architectural Wall Cladding with Openings

Wall cladding installations need exact cutouts for windows, doors, and fixtures. Waterjet cutting delivers precise openings while maintaining the stone’s structural and visual characteristics, ensuring panel integrity throughout the installation.

Slate Variety Considerations

Slate showcases diverse textures and colors, depending on its origin and composition. Dense slate, such as Pennsylvania blue-black, offers durability and resists splitting, making it ideal for high-traffic areas. Softer varieties provide unique hues that introduce warmth and subtle variation to spaces, giving each project a distinct character.

Waterjet cutting technology delivers precision and consistency across all slate types. It preserves natural textures, layered structures, and color integrity, while enabling intricate patterns and detailed inlays without damaging the stone.

This combination of slate’s adaptability and precise fabrication allows for creative freedom and efficient installation. Contractors receive pieces ready to fit seamlessly, while clients benefit from floors and surfaces that provide lasting beauty, structural reliability, and visual depth.

Enhancing Material Efficiency

Premium slate is a valuable material, and efficient use is essential for both cost management and design quality. Waterjet cutting enhances yield by reducing the risk of edge separations and fractures, preserving the integrity of each piece. This careful approach ensures that even high-value slate is used effectively throughout the project.

Complex patterns and intricate designs are executed with precision on the first attempt. Accurate cuts minimize the need for rework, allowing contractors to maintain smooth workflows and consistent results. Each component reflects the intended design while protecting the natural structure and texture of the slate.

By maximizing material efficiency, projects benefit from predictable requirements and reduced waste. High-quality slate retains its aesthetic appeal and durability, supporting visually striking designs without unnecessary loss. This approach combines sustainability with practical advantages, making every project both efficient and elegant.

Edge Quality and Natural Aesthetic

Waterjet cutting preserves the natural cleft texture of slate edges, maintaining the stone’s organic appearance. Each cut reflects the material’s inherent patterns, contributing to a cohesive and visually engaging surface. This precision enhances the overall design, allowing the stone’s character to remain the focal point in any application.

Flooring, walls, countertops, and decorative elements all benefit from edges that align seamlessly with the stone’s natural properties. The consistency of waterjet cuts ensures that each component fits precisely, supporting smooth installation and a refined presentation. Contractors can work confidently, knowing the pieces will integrate effortlessly into the intended layout.

Preserving the natural aesthetic of slate through careful cutting elevates both interior and exterior projects. The combination of precise edges and authentic texture enhances the visual impact and long-term durability of the installation. Every piece reflects craftsmanship and thoughtful attention to the material’s inherent qualities.

Hydro-Lazer’s Expertise in Slate Cutting

Hydro-Lazer delivers precise waterjet cutting for slate, supporting designers, fabricators, and contractors in producing high-quality, consistent pieces. From detailed medallions to practical cutouts, every component is accurately shaped while preserving the stone’s natural edges and appearance.

Cutting slate requires careful attention to its layered texture and aesthetic qualities. Hydro-Lazer maintains the integrity of each layer, preserving color, texture, and structural stability while enabling intricate, creative designs.

For professional projects, Hydro-Lazer offers the technology and expertise to ensure precision, durability, and aesthetic excellence. Every slate installation benefits from clean cuts, seamless assembly, and visually striking, long-lasting results. Bring Your Design to Life with Precision Waterjet Cutting — Get a Free Quote!