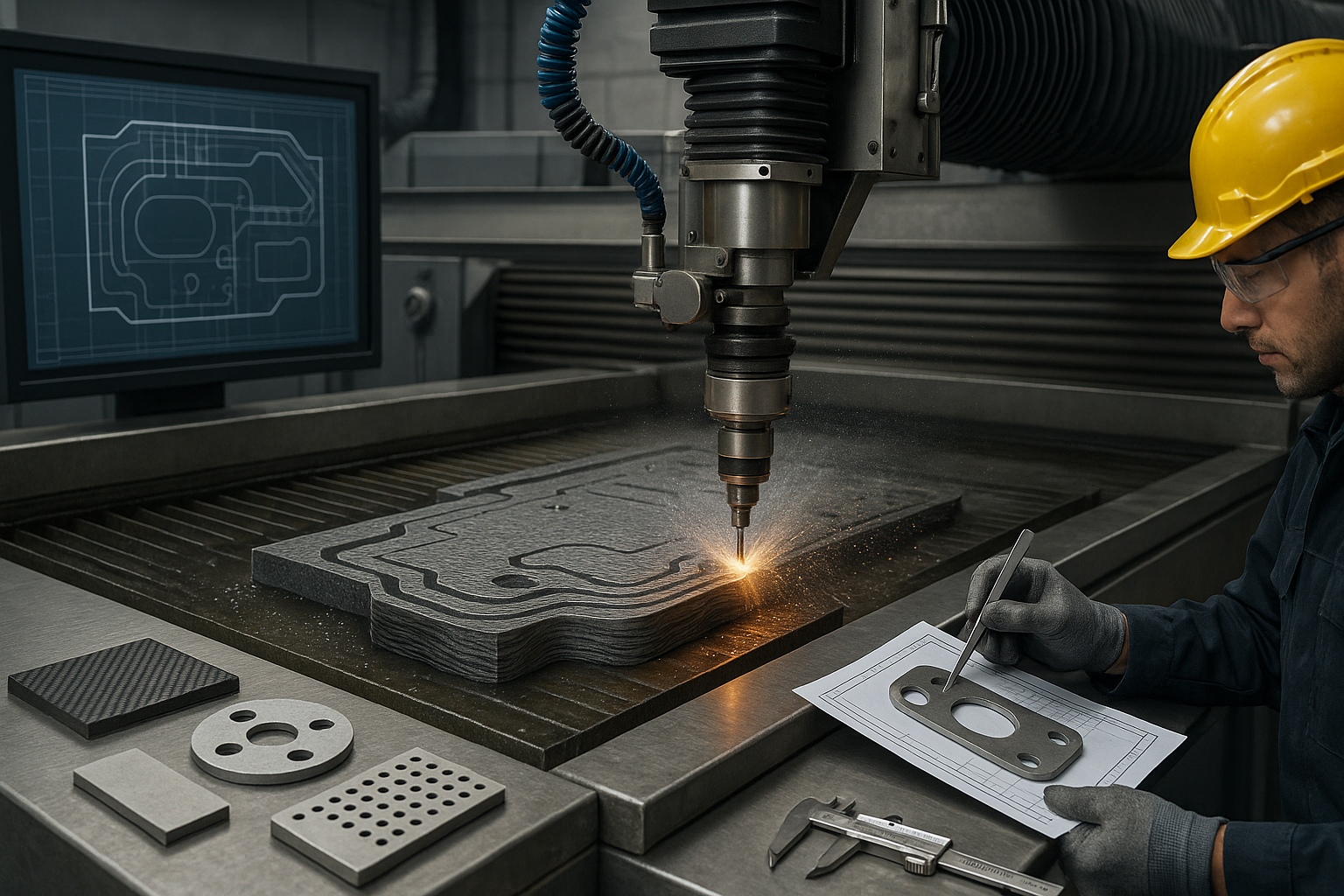

In today’s world of accelerated innovation, standard manufacturing solutions just don’t cut it—literally. From aerospace composites to nanomaterial-enhanced prototypes, engineering teams are grappling with designs and materials that push beyond traditional boundaries. That’s where Hydro-Lazer comes in. Specializing in custom water jet cutting, Hydro-Lazer transforms cutting challenges into custom-engineered solutions—with micron-level precision and unmatched material versatility.

When tolerances are tight, materials are exotic, and performance is critical, Hydro-Lazer’s custom water jet cutting services become the bridge between ambitious design and manufacturable reality.

Why Standard Cutting Methods Fall Short

Standard CNC or laser systems often buckle under complex geometries or heat-sensitive materials. Intricate internal cavities? Multi-material interfaces? Medical-grade finishes? Forget it. These aren’t one-size-fits-all challenges. They demand a smarter, more adaptive approach. Hydro-Lazer’s custom water jet cutting unlocks the possibilities—without heat distortion, mechanical stress, or compromise on edge quality.

Unlike thermal cutting methods, our cold-cutting precision maintains the structural and chemical integrity of advanced materials, even those with specialty coatings or layered composites.

The Custom Engineering Matrix – Your Innovation Ally

Hydro-Lazer doesn’t just offer a service—we offer solutions, engineered to your exact needs. Whether you’re an R&D lead iterating a prototype or a manufacturing engineer optimizing for performance, we speak your language. Our custom water jet cutting is intelligently mapped across key engineering challenge categories:

Geometric Complexity Solutions

- Multi-axis and multi-dimensional cutting

- Complex internal features, interlocking assemblies

- Precision fits with tolerance stack-up management

Advanced Material Engineering

- CFRPs, GFRPs, hybrid composites

- Heat-sensitive metals and coatings

- Bio-composites and sustainable materials

Functional Integration Solutions

- Lightweighting strategies

- Integrated mechanical or electronic features

- Custom shapes for performance-specific use cases

Rapid Innovation Support

- Concept-to-reality acceleration

- Iterative prototype refinement

- CAD/CAM integration for quick pivots

Hydro-Lazer’s process doesn’t just deliver parts—it delivers performance-ready components designed with your end function in mind.

Advanced Material Mastery—From Aerospace to Biotech

Material diversity is where custom water jet cutting shines brightest. From titanium alloys used in high-temperature environments to shape-memory polymers destined for next-gen medical devices, Hydro-Lazer’s cutting-edge capabilities unlock performance across industries. We handle:

- Superalloys and aerospace metals

- Smart materials with embedded functions

- Nanomaterial composites for lightweight strength

- Biocompatible surfaces with zero contamination

Custom doesn’t mean complicated—it means prepared, with the right process, every time.

Custom Process Innovation—Cutting Smarter, Not Just Sharper

At Hydro-Lazer, innovation isn’t just a buzzword—it’s baked into our process. Our custom water jet cutting solutions include:

- Adaptive Cutting Strategies – Real-time tuning, multi-pass options, and surface finish optimization.

- Precision Control Systems – Custom fixturing, edge quality refinement, and dimensional accuracy enhancements.

- Integrated Technologies – CAD/CAM customization, robotic automation, in-line quality checks, and scalable workflows.

We don’t just cut; we co-create. Every project is an opportunity to push boundaries, improve performance, and shorten development cycles.

Engineering Partnership, Not Just Service

You don’t need another vendor—you need a partner. Hydro-Lazer collaborates from blueprint to build, offering:

- Design Optimization – From material selection to manufacturability checks

- Technical Consultation – Stress analysis, tolerance assessments, and test planning

- Innovation Support – R&D collaboration, validation protocols, and tech transfer

We exist to make your ideas real—with accuracy, agility, and accountability.

The Hydro-Lazer Delivery Framework – Built for Custom Success

Our approach to custom water jet cutting ensures consistency, scalability, and confidence.

- Project Planning – We assess feasibility, define specs, and map every phase.

- Solution Development – Prototyping, testing, optimizing.

- Production Implementation – Seamless scaling, documentation, and support.

- Ongoing Partnership – Continuous improvement through feedback loops and innovation cycles.

Your Custom Journey Starts Here

The pathway to custom precision begins with a single conversation. Hydro-Lazer makes it simple to engage:

- Initial Consultation – Define the challenge

- Custom Strategy – We design the best-fit cutting solution

- Prototype & Iterate – Test, refine, validate

- Scale with Confidence – Production-ready from day one

- Grow Together – We stay with you through every evolution

When your project demands precision, complexity, and performance beyond the norm, custom water jet cutting from Hydro-Lazer becomes more than a process—it becomes a competitive edge.

Let’s engineer the impossible. Together.