It started with a sketch—an aerospace engineer’s rough drawing of a titanium component with tolerances too tight for traditional cutting methods. Others said it couldn’t be done. But at Hydro-Lazer, we looked at it differently. Not as a limitation, but as a challenge worth solving. Within weeks, that sketch became a precisely engineered part, cut with micron-level accuracy using our custom water jet cutting process.

That’s the power of collaboration, innovation, and process transparency. And that’s exactly what we do every day at Hydro-Lazer. This is the story of how your vision becomes reality—step by step.

The Vision Phase – Where Ideas Take Shape

Beyond the Blueprint: Understanding Your True Requirements

Every great product starts with an idea—but turning that idea into a tangible, high-performing part requires deep collaboration. At Hydro-Lazer, our custom water jet cutting journey begins with a conversation. We ask for specs and why those specs matter. We want to understand the function, the stress points, the materials you’re considering, and the vision behind your design.

From here, we guide you through material selection based on cut quality, edge durability, and cost-efficiency. Whether you’re working in stainless steel, glass, carbon fiber, or ceramic, we match your needs with the ideal cutting strategy. That balance of cutting-edge tech and human-centered design defines Hydro-Lazer’s philosophy.

The Precision Planning Stage

Engineering Excellence: Where Science Meets Art

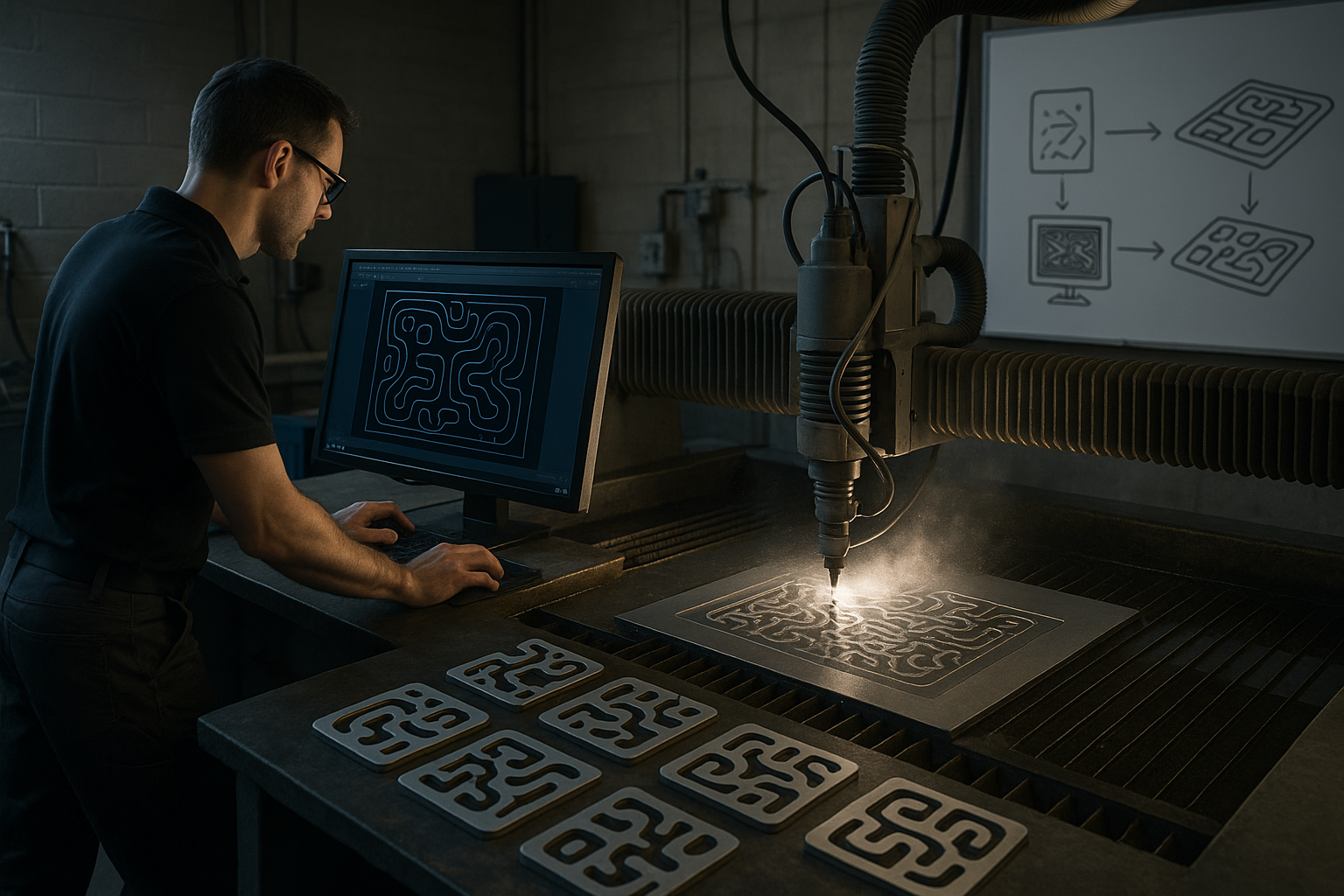

Before a single drop of high-pressure water is released, our engineering team translates your design into a digital roadmap. We use advanced CAD software to optimize every line and curve—because precision is cutting clean edges and cutting smart.

Toolpaths are programmed to reduce heat zones, eliminate distortion, and preserve material integrity. Our planning process for custom water jet cutting also includes rigorous quality checkpoints—from verifying tolerances to pre-processing material inspections. It’s science and art, married in every millisecond of planning.

The Cutting Edge Process

Pressure, Precision, and Perfection

Now the magic happens. Using ultra-high-pressure water—sometimes up to 90,000 psi—mixed with an abrasive like garnet, we begin the custom water jet cutting process. It’s cold-cutting, so there’s no thermal stress. No warping. Just clean, crisp edges that honor your design.

Real-time monitoring allows us to make micro-adjustments as we go, ensuring flawless accuracy on even the most intricate cuts. And we hope for perfection and check for it as we go. That’s the Hydro-Lazer difference: live accountability from start to finish.

Post-Cutting Excellence

The Final Touch: Ensuring Perfection

The cut is only the beginning. Once the part emerges from the water jet, it goes through edge refinement, deburring, and finishing based on your specifications. Whether you need ultra-smooth edges for consumer products or ruggedized surfaces for industrial use, we deliver.

Before anything leaves our facility, it passes a comprehensive quality assurance process. Dimensional checks. Surface inspections. Durability reviews. Because when we say custom water jet cutting, we mean tailored down to the micron.

Delivery and Beyond

Your Success is Our Success

Once approved, your parts are packaged with care and shipped according to your timeline—whether local across Pennsylvania or national. Need installation support or additional prototyping? We’ve got you.

And after delivery? We follow up. Because one project usually leads to another. We cut material and build relationships. That’s why our partners in aerospace, automotive, architecture, and manufacturing keep coming back. Because Hydro-Lazer is a service and a solution.

Why Hydro-Lazer Is the Leader in Custom Water Jet Cutting

There are plenty of shops that offer water jet services. But not many show you the process. Even fewer walk you through it like a partner. And almost none invest in your success like we do.

At Hydro-Lazer, we believe in custom water jet cutting that is precise, transparent, and personal. We educate you. We collaborate with you. And we engineer results that exceed your expectations. That’s why clients trust us with everything from one-off prototypes to full production runs.

Start Your Journey with Hydro-Lazer

Let’s bring your idea to life—together. Whether you need aerospace-level accuracy or intricate architectural detailing, we’re ready to collaborate.

Hydro-Lazer. Custom water jet cutting—done right, every time.