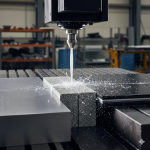

Precision and efficiency are crucial for industrial projects, especially when tight tolerances and high-quality finishes are required. In Freeport, PA, metal cutting services are rising to meet these demands with advanced waterjet technology. From custom steel brackets to intricate components, waterjet cutting delivers unmatched accuracy while preserving the material’s strength and structure.

Industrial teams in Freeport increasingly rely on waterjet cutting for projects that require both speed and meticulous detail. The technology allows for clean, precise cuts without heat-affected zones, maintaining the integrity of metals and reducing post-processing work. This ensures components fit perfectly and perform reliably in their applications.

Waterjet cutting services provide consistent results for complex designs and diverse materials. Hydro-Lazer’s expertise demonstrates how this method supports tight deadlines and exacting specifications, making it a trusted choice for companies seeking precision, durability, and efficiency in metal fabrication.

The Technology Behind the Cut

Waterjet Physics: Abrasive Cold Cutting

Waterjet cutting employs ultra-high-pressure water (up to 60,000 PSI) combined with garnet abrasive to slice through metals. This cold cutting process maintains the material’s original properties and avoids heat-affected zones.

Maintenance supervisors needing precise replacement parts and quality control managers requiring tight tolerances benefit from consistent results. Hydro-Lazer’s metal cutting services Freeport PA ensure exacting accuracy with minimal secondary operations.

Laser Physics: Thermal Cutting

Laser cutting uses a focused light beam to remove material, often assisted by gases like oxygen or nitrogen. While effective for thin metals, the heat can alter material structure and lead to slight warping. Industrial engineers recognize that for thick steel or aluminum components, careful attention to finishing is essential.

Waterjet technology maintains uniform quality across materials and thicknesses, providing reliable precision for Freeport-area projects.

Cold Cutting Advantages

Waterjet’s cold cutting process avoids structural changes, preserves mechanical properties, and allows for precise tolerances across complex parts. Thermal cutting methods may require additional steps to ensure material integrity. Hydro-Lazer’s approach in Freeport, PA, ensures components maintain strength, dimension, and surface finish without extra handling.

Five Advantages for Industrial Metal Projects

1. Zero Heat-Affected Zones

Waterjet cutting eliminates heat-related material changes. Hardened steel, aluminum, or tempered metals retain their strength and form. Applications include structural brackets, precision gears, and replacement parts.

Hydro-Lazer’s metal cutting services Freeport PA reduce the need for additional annealing or straightening, shortening production cycles and maintaining project schedules.

2. Material Versatility

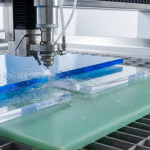

Waterjets can cut metals, composites, stone, and rubber. Single-source capability simplifies procurement for projects requiring multiple materials. Architects, engineers, and project managers benefit from consistent results across diverse components.

Hydro-Lazer’s services in Freeport, PA, offer reliable performance across a wide range of industrial applications, supporting efficiency and coordination.

3. Superior Edge Quality on Thick Materials

Waterjets maintain consistent kerf width through thick materials, producing clean edges without taper or dross. This is particularly valuable for steel plates exceeding 1 inch, where precision is critical. Freeport manufacturers can achieve ready-to-assemble components with reduced post-processing, enhancing workflow and productivity.

4. Predictable Operational Costs

Waterjet cutting requires only garnet abrasive, eliminating the need for consumable gases used in laser cutting. This consistency supports stable per-piece costs for batch production and high-volume operations. Freeport, PA, project managers can plan budgets with confidence, knowing material and process costs remain predictable.

5. Complex Geometries with Precision

Waterjets cut intricate patterns with minimal risk of micro-fractures or warping. Applications include decorative metalwork, precision gaskets, and detailed mechanical components. Hydro-Lazer’s metal cutting services Freeport PA deliver parts that meet exact specifications, reducing scrap and ensuring first-time quality.

Situations Favoring Laser Cutting

Laser cutting excels with thin metals and designs that follow clear, repetitive patterns. Its efficiency allows rapid processing while maintaining clean, precise edges. Industries that handle sheet metal or standardized components benefit from the speed and consistency that laser technology provides.

For projects requiring intricate patterns and delicate materials, waterjet cutting offers remarkable precision. It preserves material integrity while adapting to a wide variety of shapes and thicknesses. Combining expertise with advanced technology ensures that each cut meets high standards for quality and accuracy.

Integrating the right cutting method for each project enhances production efficiency and maintains optimal results. When precision, speed, and versatility align, workflows become smoother and more dependable. This approach highlights the strengths of both laser and waterjet techniques, creating reliable solutions for diverse manufacturing needs.

Why Freeport PA Enhances Project Outcomes

Freeport, PA, thrives as a hub for manufacturers and fabrication shops across Western Pennsylvania. Its location encourages swift project coordination and easy access to expert guidance. The local industrial community brings extensive knowledge of regional fabrication requirements, supporting smooth operations and effective planning.

Hydro-Lazer’s waterjet cutting services add precision and reliability to Freeport’s manufacturing environment. The technology accommodates diverse materials and designs while maintaining consistent quality. This capability enhances workflows, ensuring projects proceed efficiently and meet established standards.

The combination of Freeport’s industrial expertise and advanced cutting services strengthens project outcomes. Close collaboration and well-coordinated resources foster timely completion, adaptable solutions, and dependable results for a wide range of fabrication needs.

Choosing the Right Approach for Precision

Precision, material versatility, and consistent performance are key considerations when selecting cutting methods. Hydro-Lazer’s waterjet metal cutting services in Freeport, PA, deliver accurate results across a wide range of industrial applications. Plant managers, engineers, and project coordinators benefit from components that maintain dimensional accuracy and require minimal finishing.

The waterjet process accommodates diverse materials and thicknesses, ensuring each project aligns with exact specifications. Reliable performance and attention to detail help streamline production and maintain high-quality standards throughout the fabrication process.

Collaborating with Hydro-Lazer in Freeport, PA, enables smooth planning and execution of precision metal cutting projects. The integration of advanced technology and local expertise supports efficient workflows, helping projects achieve consistent and dependable outcomes.