In today’s design-forward world, glass isn’t just glass—it’s a canvas for creativity, function, and precision. Whether it’s a custom mirror for a high-end interior, a flawless panel for a luxury shower door, or a branded glass feature in a retail space, the expectations for glass cutting services have changed dramatically. Clients want accuracy. They want versatility. Most of all, they want zero margin for error. That’s exactly what Hydro-Lazer delivers.

While traditional thermal and mechanical methods have dominated the industry for decades, they often fall short in today’s market. Edge chipping, microfractures, and warped surfaces are common frustrations. Designers and engineers alike are tired of compromising design dreams for technical limitations. Enter Hydro-Lazer—the glass cutting company that’s rewriting the rules with waterjet precision.

Why Traditional Methods Aren’t Cutting It Anymore

Conventional glass cutting tools—diamond wheels, CO2 lasers, and scoring knives—might do the job, but they often come with baggage. Cracks. Chips. Stress marks. Especially when cutting tempered glass, laminated panels, or intricate shapes, the risks multiply. Heat-based techniques distort the surface, and mechanical scoring can’t handle custom-cut glass without drama.

Plus, the more complex the project, the higher the waste rate. Trying to cut unique shapes or precision details with traditional tools is like using a butter knife for surgery—blunt, risky, and ineffective.

The Hydro-Lazer Difference: Cold, Clean, Creative Cuts

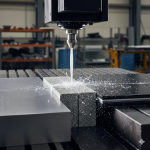

Hydro-Lazer’s waterjet-based glass cutting services bypass every one of those traditional pitfalls. Here’s how their process turns fragile glass into flawless results:

1. Cold-Cutting Precision

Waterjet cutting doesn’t use heat, so there’s no warping, stress, or microfractures. That makes it ideal for sensitive glass products like double-pane glass, safety glass, or stained glass installations. Even replacement glass gets a replica without compromise.

2. Smooth, Clean Edges Every Time

The abrasive waterjet produces silky-smooth cuts with no post-processing needed. No polishing. No grinding. No rework. It maintains the glass clarity, strength, and structure as-is—something traditional methods simply can’t promise.

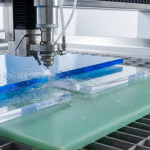

3. Complex, Intricate Shapes Made Simple

Need curves, slots, notches, or elaborate inlays? Hydro-Lazer can turn your CAD designs into real-world results, fast. Whether it’s logos on custom mirrors, artistic mosaics, or unusual glass panel shapes, their precision is second to none.

4. Versatility Across Glass Types

From thick architectural pieces to delicate frosted accents, Hydro-Lazer handles every glass option imaginable. Laminated, tempered, patterned, or clear—if it’s glass, they can cut it. And they’ll cut it to size, perfectly.

Real Glass Cutting Services for Real-World Projects

Hydro-Lazer works across a wide range of industries, from concept to completion. You’ll find their cuts in:

- Architectural Design: Structural glass panels, glass railings, and custom signage.

- Interior Design: Designer mirrors, high-end shower enclosures, and table tops.

- Retail & Hospitality: Decorative glass features, logos, and fixtures.

- Electronics & Manufacturing: Precision-cut display glass and substrates.

- Art & Specialty Applications: Custom-cut glass for sculptures, stained glass, and fine art installations.

Their ability to handle small-batch artisanal work as well as high-volume commercial runs sets them apart. Quality isn’t an afterthought—it’s the foundation.

Hydro-Lazer’s Seamless Client Experience

From the moment you reach out, Hydro-Lazer’s process is polished. Their in-house engineering team supports you through file prep and material selection. Every project is treated with care, and every delivery is on time. North American clients trust Hydro-Lazer because they combine high-end glass cutting services with real, human-centered customer service.

Whether you’re an architect needing perfectly matched replacement glass or a creative pro seeking one-of-a-kind glass products, Hydro-Lazer’s commitment to precision and partnership makes your vision feel possible—and easy.

Cutting Glass Without Limits

Hydro-Lazer doesn’t just provide glass cutting services—they provide a new way of thinking about glass. No heat. No damage. No limits.

If your project demands precision, creativity, and pristine results, it’s time to ditch the old methods. Embrace the power of waterjet technology. Work with a team that respects your vision and exceeds your expectations—cut after cut.

Bring your custom glass project to life with precision and confidence. Contact Hydro-Lazer today for a quote and consultation.