In today’s high-performance industries—from aerospace to medical manufacturing—ceramics are everywhere. These materials are prized for their strength, resistance to heat and wear, and biocompatibility. But with all those benefits comes one stubborn downside: ceramics are notoriously difficult to cut. Traditional mechanical and laser cutting methods often create more problems than solutions, introducing heat-affected zones, microfractures, or uneven edges.

That’s where Hydro-Lazer steps in. With over 30 years of experience and some of the most advanced abrasive waterjet cutting machines in the industry, Hydro-Lazer has become the trusted leader in ceramic waterjet cutting services. Whether you’re dealing with porcelain tile or a zirconia component for a satellite, Hydro-Lazer delivers clean, burr-free, and high-quality results that protect the integrity of your materials, every time.

Ceramics: Tough to Use, Tougher to Cut

Ceramics are incredible, but they’re a pain to work with if you don’t have the right tools. They’re hard—great. But they’re also brittle. That means even a small amount of heat or vibration can cause cracking, chipping, or internal stress that ruins the piece. This is why laser cutting and mechanical methods often fall short. Add in the demand for tight tolerances and complex geometries, and you’ve got a real engineering headache.

But what if you could get perfect edges, zero heat distortion, and virtually any shape you need—without ever touching the material with a blade?

Why Hydro-Lazer’s Ceramic Waterjet Cutting Services Stand Apart

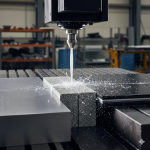

Hydro-Lazer uses cutting-edge abrasive waterjet cutting technology—a cold cutting process that relies on ultra-high-pressure water mixed with abrasive particles to slice through ceramic without heat, stress, or damage.

1. No Heat, No Distortion

Forget heat-affected zones. Hydro-Lazer’s ceramic waterjet cutting services eliminate thermal distortion and the need for post-process finishing. The result? Ceramics that maintain their integrity and strength from start to finish.

2. Precision You Can Count On

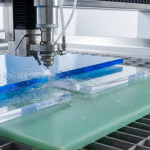

Whether it’s a medical device casing with micrometer-level tolerances or an intricate mosaic tile, Hydro-Lazer’s CNC-guided waterjet machines provide consistent, clean, burr-free edges—ready for immediate assembly or installation.

3. Versatility Across Materials and Thicknesses

From ultra-thin substrates to industrial ceramics inches thick, Hydro-Lazer handles it all. Their machines can cut porcelain, alumina, zirconia, ceramic composites, and even glass ceramics, adapting to the specific needs of each material type.

4. No Tool Wear, No Stress

Because waterjet cutting is a non-contact method, there’s no risk of tool wear or vibration-induced damage. This makes it perfect for delicate or high-value components where precision and material preservation are critical.

Applications That Demand Precision

Hydro-Lazer’s ceramic waterjet cutting services are used in industries where performance isn’t optional—it’s mission-critical.

- Aerospace: Heat shields, ceramic liners, and wear-resistant parts that perform at extreme temperatures.

- Medical Devices: Biocompatible ceramic housings and insulators made to exacting standards.

- Electronics: Ceramic circuit boards and substrates requiring tight tolerances and smooth finishes.

- Architecture: Custom-cut tiles, decorative panels, and intricate inlays that bring design visions to life.

- Manufacturing: Insulators, gaskets, spacers, and specialized tools with demanding specs.

And with full in-house engineering support, Hydro-Lazer doesn’t just cut your parts—they help you design them smarter from the start.

Built for Engineers, By Experts

Hydro-Lazer isn’t just a service provider. They’re a partner in the product development process. Their team works closely with engineers and designers to optimize parts for waterjet cutting, ensuring the best outcomes with minimal waste and maximum material utilization.

Need CAD support? They’ve got it. Want to fine-tune tolerances? No problem. From prototype to production, Hydro-Lazer’s streamlined workflow guarantees fast turnarounds, reliable scaling, and consistent quality across every job.

Design Smarter: Tips for Your Next Ceramic Project

Thinking about waterjet cutting for your next ceramic component? Here’s how to make the most of it:

- Use precise CAD files—DXF or DWG formats are ideal.

- Define clear material specs and thicknesses upfront.

- Allow for kerf width in complex designs (typically 0.03”–0.05”).

- Collaborate with Hydro-Lazer early to optimize part geometry and minimize costs.

Their engineering team is always ready to provide input, whether you’re cutting a single prototype or preparing for a full production run.

Precision Meets Performance—Every Time

In a world where materials are becoming more advanced and design tolerances are tighter, traditional cutting methods simply can’t keep up. Hydro-Lazer’s ceramic waterjet cutting services offer the precision, cleanliness, and reliability that industries demand.

No heat. No stress. No compromise.

So if your ceramic parts require clean, accurate cuts without the risk of damage, whether they’re for space, surgery, or showroom floors, Hydro-Lazer is ready to help.

Need clean, accurate cuts for your ceramic components? Contact Hydro-Lazer today for a custom quote and expert guidance on your next project.