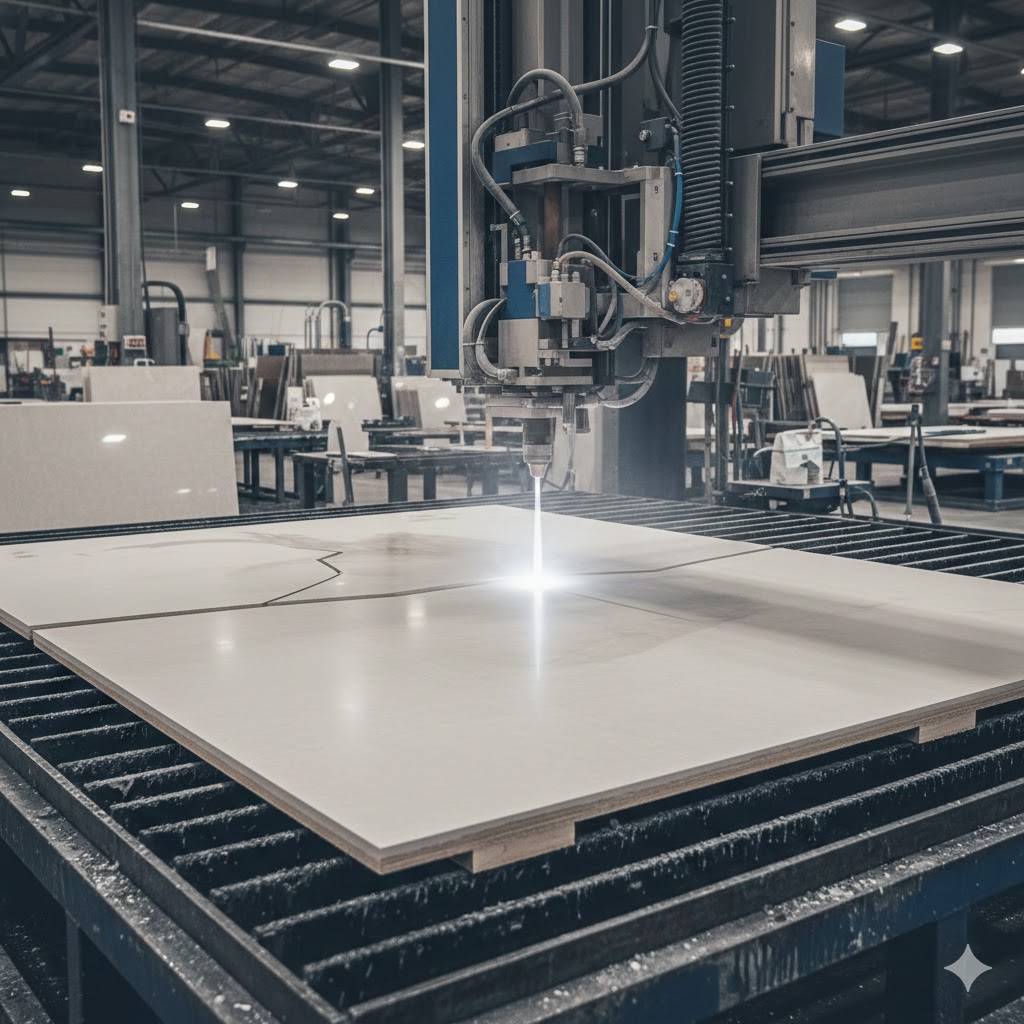

A large-format porcelain slab measuring 63 inches by 126 inches can weigh over 200 pounds. Cutting it into a precise shape for a countertop or wall panel requires careful handling and precise control. Even small imperfections during traditional cutting can create internal stress. Hydro-Lazer provides porcelain tiles waterjet cutting solutions that maintain the integrity of large slabs while achieving precise custom dimensions and complex shapes with consistency.

Waterjet cutting uses high-pressure water combined with fine abrasive particles to remove material without applying mechanical force. This method reduces the risk of micro-fractures and edge damage and allows complex geometries to be produced without repositioning the slab. It ensures reliable fabrication for oversized porcelain slabs that require exacting precision.

Why Larger Porcelain Slabs Require Special Attention

Porcelain is exceptionally hard, rated at Mohs 7 to 8, which provides excellent surface durability while presenting challenges during cutting. The material has high compressive strength but low tensile strength, which makes it prone to cracking if stress is applied unevenly. Large slabs amplify these characteristics because of their weight, low flexibility, and lack of reinforcement.

Handling heavy slabs introduces subtle stress points. Vibrations from cutting equipment and thermal expansion from friction can cause hairline cracks. Support systems must maintain stability across the entire slab surface to prevent bending. Fabrication techniques that succeed with smaller tiles may create complications when applied to oversized slabs, so selecting an approach that preserves material integrity is essential.

Size Categories and Cutting Considerations

Porcelain slabs come in standard large formats, oversized slabs, and maximum dimension slabs, each presenting specific technical needs. Porcelain tiles waterjet cutting addresses these needs efficiently.

Standard Large-Format Tiles (24 inches by 48 inches to 32 inches by 64 inches)

These slabs can be managed with conventional saws, but edge chipping remains a concern, particularly with glazed surfaces. Waterjet cutting delivers smooth edges without micro-fractures and improves the consistency of multiple pieces for installation. Common applications include floor planks, shower walls, and backsplash panels.

Oversized Slabs (48 inches by 96 inches to 63 inches by 126 inches)

The weight and dimensions of these slabs require precision cutting without vibration or mechanical stress. Waterjet cutting creates straight and curved lines with consistent results across the entire surface. It allows fabrication of kitchen islands, continuous countertops, wall panels, and furniture surfaces with minimal material waste. This approach ensures repeatable accuracy that traditional saws may struggle to maintain.

Maximum Dimension Slabs (63 inches by 126 inches and larger)

For slabs at this scale, precise material handling and stress-free cutting are crucial. Waterjet cutting enables complex shapes, interior cutouts, and radius edges while maintaining slab stability. Applications include extensive countertop runs, architectural wall panels, and custom furniture surfaces. Large-scale projects benefit from waterjet cutting by ensuring slabs retain their full structural strength and appearance.

Stress-Free Cutting Mechanics

Waterjet cutting removes material without applying pressure, vibration, or heat that could compromise a slab. Traditional saws create cutting forces that may transfer through the entire slab, causing edge chipping, minor cracks, or dimensional inconsistencies.

Waterjet cutting uses a high-pressure water stream with abrasive particles to erode porcelain. This cold cutting process keeps temperatures low, prevents thermal expansion, and maintains dimensional stability. The slab remains fully supported on the cutting table, eliminating stress from weight and handling. Fabrication outcomes are consistent, and slab quality is preserved.

Complex Shapes and Custom Fabrication

Waterjet cutting opens possibilities for precise geometric designs in large-format porcelain. Straight cuts achieve tolerances within ±0.003 inches over long distances, supporting seam-matched installations. Curves, radius edges, and interior cutouts such as sinks, faucets, or electrical outlets can be produced in a single pass without repositioning the slab.

Custom angles and miters, waterfall edges, and decorative inlays can be fabricated with reliable precision. Sequential slabs can be cut to match patterns for book-matched installations, providing a seamless visual appearance for continuous surfaces. Waterjet cutting allows designs to be fully realized without compromising the structural integrity of the porcelain.

Custom Dimensions

Porcelain slabs often need dimensions that exceed standard manufacturer sizes. Waterjet cutting enables precise width, length, and angled cuts to meet project specifications. This capability is useful for narrow countertops, angled backsplash pieces, furniture-integrated surfaces, and threshold transitions.

Custom fabrication ensures that designs are supported by available materials without forcing compromises on size or shape. Slabs can be tailored to fit architectural requirements, providing flexibility in project planning and execution. Hydro-Lazer facilitates these precision cuts while minimizing material waste and protecting investments.

Material Investment Protection

Porcelain slabs represent a significant investment. Using fabrication methods that preserve structural integrity and ensure accuracy supports efficient project execution and cost management. Waterjet cutting provides reliability and precision for every slab, supporting large-scale projects and complex designs.

Hydro-Lazer positions porcelain tiles waterjet cutting as a practical solution for fabricators, contractors, and designers seeking consistent results. It ensures that large-format porcelain slabs are transformed into precisely fabricated surfaces while maintaining their strength, quality, and appearance. This method supports confident planning and execution for any project requiring oversized or custom dimension porcelain.