In industrial manufacturing, where precision and quality are non-negotiable, businesses are continually looking for solutions that meet the highest standards. From custom seals to gaskets, insulation to industrial components, the need for rubber cutting services is ubiquitous. Enter Hydro-Lazer, a leader in the field of custom rubber cutting solutions. With their cutting-edge waterjet cutting technology, they have redefined what’s possible when it comes to creating high-quality, custom rubber products.

Understanding the Need for Rubber Cutting Services

At its core, rubber cutting is an essential service for industries that require durable, reliable components. Rubber cutting services are not only about precision; they’re about ensuring that every part fits seamlessly into its intended application. Custom gaskets, seals, and insulation play a pivotal role in industries like automotive, aerospace, manufacturing, and medical equipment. The demand for rubber parts that maintain both performance and longevity is ever-growing, and that’s where Hydro-Lazer excels.

But what makes their rubber cutting services stand out from the rest?

The Precision of Waterjet Cutting Technology

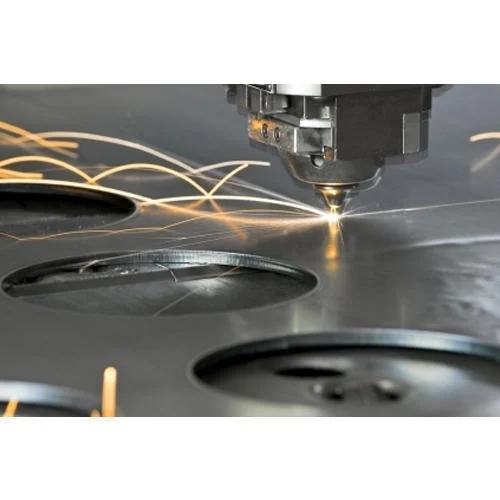

Imagine cutting through a material as tough as rubber without compromising its integrity. This is where waterjet cutting technology shines. Unlike traditional cutting methods, which often introduce heat and can distort or damage materials, waterjet cutting uses a high-pressure stream of water, sometimes combined with abrasive materials, to create precise cuts. This cutting process ensures that the rubber remains unscathed, without any heat-related distortion, which is crucial for industries relying on the integrity of their components.

Hydro-Lazer’s custom rubber cutting services are designed to provide highly precise, clean cuts that are unmatched in the industry. Whether you’re dealing with a simple shape or a complex, intricate design, waterjet cutting ensures that every rubber product meets the exact specifications. The precision and versatility of this technology make it an invaluable tool for manufacturers across various sectors.

Why Choose Hydro-Lazer’s Rubber Cutting Services?

There are plenty of options out there when it comes to rubber cutting, but Hydro-Lazer stands head and shoulders above the competition. What sets them apart? Their commitment to quality, their use of state-of-the-art technology, and their ability to tailor their rubber cutting services to the specific needs of each client.

One of the biggest advantages of waterjet cutting is its versatility. Whether you need custom die-cutting rubber components for industrial machinery or high-performance seals for the aerospace industry, Hydro-Lazer can accommodate nearly every request. The ability to cut through various types and thicknesses of rubber makes it possible to achieve precise, customized solutions for every project.

The best part? These rubber cut services are cost-effective. Traditional cutting methods, like die-cutting, often require expensive tooling and setup costs, but with waterjet technology, there are no molds to create, no complicated setup processes. This makes Hydro-Lazer’s rubber cutting services a cost-efficient solution, saving both time and money for their clients.

Industries Served by Hydro-Lazer’s Rubber Cutting Services

The scope of rubber cutting services extends far beyond what many might initially think. Hydro-Lazer has built a reputation for serving industries where precision and quality are paramount. Here are just a few examples of industries that benefit from their custom rubber cutting solutions:

- Automotive: Custom rubber seals, gaskets, and insulation components that ensure vehicles run smoothly and efficiently.

- Aerospace: Precision-cut rubber parts designed to withstand extreme conditions, ensuring the safety and performance of aircraft.

- Manufacturing: Rubber products tailored for machinery, tools, and equipment to improve durability and performance.

- Medical: Rubber components that meet stringent industry standards for medical devices and equipment.

With the ability to cut rubber to any specification, Hydro-Lazer is uniquely positioned to provide solutions for nearly any application, all while maintaining a focus on high-quality, clean cuts that never compromise the material’s integrity.

The Impact of Hydro-Lazer’s Rubber Cutting Solutions

At the heart of Hydro-Lazer’s mission is its ability to empower industries to create better products, faster and more efficiently. The combination of precision, speed, and cost-effectiveness is what makes their rubber cutting services the go-to choice for businesses across multiple sectors.

Whether you need a rubber die cut product for a new machine part or a custom-designed die cut material for sealing applications, Hydro-Lazer is committed to delivering high-quality rubber cutting solutions that meet the exacting standards of its clients. They don’t just provide a service; they provide a partnership that allows businesses to thrive in an increasingly competitive marketplace.

Hydro-Lazer: A Trusted Partner for Custom Rubber Cutting

Businesses need solutions that are both efficient and reliable. Hydro-Lazer’s rubber cutting services offer precisely that—along with the added benefits of precision, versatility, and cost-effectiveness. Their state-of-the-art waterjet technology ensures that every rubber component they produce is of the highest quality, making them the preferred partner for companies across a wide range of industries.

When you choose Hydro-Lazer, you’re not just getting a rubber cutting service—you’re getting a trusted partner who is dedicated to helping you succeed.