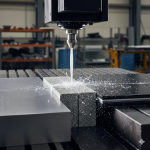

In manufacturing, a single micron can mean the difference between perfect function and catastrophic failure.

That’s not a scare tactic—it’s the reality of modern precision manufacturing. Whether you’re designing a prototype or scaling to full production, the cost of inaccuracy is no longer tolerable. That’s why Hydro-Lazer’s water jet service isn’t just a tool—it’s a full-spectrum solution designed for companies who demand excellence from start to finish.

At Hydro-Lazer, we’re not just cutting materials—we’re cutting tolerances, trimming down timelines, and removing uncertainty from your production pipeline. Our advanced water jet service is engineered to meet micron-level demands, from conceptual prototyping to long-term high-volume production, with consistency you can measure and trust.

The Precision Journey: From First Cut to Full Production

Think of precision not as a destination, but as a continuum. From the earliest spark of an idea to mass production, Hydro-Lazer’s water jet service supports every stage with systematic accuracy and documented repeatability.

Phase 1: Precision Prototyping

When your design is still fluid, precision must be flexible yet unyielding. That’s where we thrive.

- Rapid iteration without compromising accuracy

- Material compatibility testing and refinement

- Tolerances as tight as ±0.0001″ from the first cut

- First article inspection for immediate validation

Hydro-Lazer enables engineers to prototype with production-grade precision, cutting down development cycles and providing confidence that what works today will scale tomorrow.

Phase 2: Precision Scaling

Proving a concept is one thing. Scaling it while maintaining tolerances? That’s mastery.

- Process repeatability through embedded quality systems

- Statistical control for dimensional reliability

- Verification at every step, from fixture to finish

With Hydro-Lazer’s water jet service, your prototype accuracy doesn’t evaporate at higher volumes—it intensifies.

Phase 3: Precision Production

Here’s where most services falter. But at Hydro-Lazer, we elevate.

- Prototype-level tolerances at scale

- Automated control systems for live parameter adjustments

- Ongoing SPC monitoring and edge-quality preservation

Every part is precision-checked, every cut is controlled, and every batch is as good as the first.

Phase 4: Precision Evolution

Precision doesn’t stand still, and neither do we.

- Integration of cutting-edge waterjet advancements

- Process refinements to meet changing spec demands

- Partnerships built on long-term optimization

At Hydro-Lazer, precision isn’t a phase—it’s our philosophy.

Micron-Level Mastery: The Technology That Delivers

Precision is nothing without capability. Our water jet service is backed by hardware, software, and human expertise calibrated for ultra-fine tolerances.

What Sets Hydro-Lazer Apart:

- Cutting Accuracy: ±0.0005″ to ±0.0001″

- Surface Finish: Consistent RA across edge geometry

- Repeatability: Verified with high-resolution CMM tools

- Real-Time Monitoring: Live adjustments for continuous control

Our technology isn’t just advanced—it’s proven, audited, and obsessively maintained to deliver flawless precision in every material.

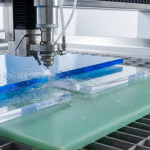

Material Precision Matrix

Every material presents a unique challenge. Our water jet service adapts with precision-tailored processes across:

- Ultra-Precision Metals & Ceramics: For aerospace, medical, and defense industries

- Precision Polymers: Perfect for electronics, automotive, and industrial components

- Composite Laminates: Seamless cutting without delamination

- Specialty Exotics: Titanium, Inconel, and carbon fiber with no thermal distortion

Hydro-Lazer doesn’t just cut materials—we engineer how they’re cut.

The Precision Advantage Framework

Hydro-Lazer isn’t your average water jet service provider. Here’s why:

- Micron-Level Repeatability: Across single prototypes or 10,000-unit runs

- First-Time Accuracy: Reduce iteration cycles and costly rework

- Precision Documentation: Full traceability with detailed process logs

- Design for Manufacturability Support: Engineering insights baked into every quote

In a market where one misalignment can ruin a batch, Hydro-Lazer’s commitment to precision gives our clients a competitive edge.

Precision Quality Systems: Not Just a Buzzword

We live and breathe quality systems. Our water jet service operates within a framework designed to ensure:

- Planning: Pre-cut simulations and spec verification

- Execution: ISO 9001 and AS9100-compliant environments

- Verification: Real-time inspection and feedback loops

- Improvement: Ongoing audits and technical reviews

Precision isn’t a checkbox—it’s a continuous discipline.

Your Precision Partnership Starts Here

Hydro-Lazer isn’t just a vendor—we’re a partner in your product’s success.

- Engineering Consultation: Optimize designs before the first cut

- Precision Prototyping: Validate fast, without sacrificing spec

- Production Scaling: Confidence across every unit

- Lifetime Support: Improvement, evolution, and innovation over time

Let’s make every micron count.

Hydro-Lazer’s water jet service isn’t just about cutting—it’s about confidence. From the very first spark of an idea to the final shipment, our precision is your advantage.