When it comes to creating stunning, intricate flooring designs, the choice of cutting technology can make all the difference.

While laser cutting has its merits, water jet floor design has emerged as the superior option for a wide range of materials and patterns.

At Hydro-Lazer, we’ve been perfecting this technology for over three decades, offering unparalleled precision and versatility in floor design creation.

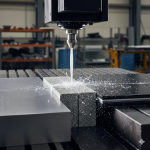

Understanding Water Jet Floor Design Technology

Water jet floor design utilizes a high-pressure stream of water, often mixed with abrasive particles, to cut through materials with incredible precision. At Hydro-Lazer, our advanced systems employ a 50,000 PSI water stream, capable of cutting through materials up to 8″ thick.

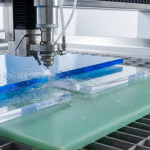

The Precision of Water Jet Floor Design

One of the key advantages of water jet floor design is its precision. Our systems at Hydro-Lazer can achieve tolerances of up to 0.003″ on certain materials, allowing for the creation of incredibly detailed and intricate floor patterns. This level of accuracy is crucial when working with delicate materials or creating complex inlays.

Versatility in Materials

Water jet floor design shines when it comes to material versatility.

Unlike laser cutting, which can be limited in the types of materials it can effectively cut, water jet technology can work with virtually any material.

This includes:

- Natural Stone: Marble, granite, slate

- Ceramic and Porcelain Tiles

- Hardwood and Engineered Wood

- Resilient Flooring: Vinyl, linoleum, rubber

- Glass and Mirrors

- Metals: For accent pieces or inlays

This versatility allows designers to create truly unique and multi-material floor designs that would be impossible with other cutting methods.

Water Jet Floor Design vs. Laser Cutting: A Comparison

While both water jet and laser cutting have their place in manufacturing, when it comes to floor design, water jet technology offers several distinct advantages:

- No Heat Affected Zone: Unlike laser cutting, water jet floor design doesn’t create heat, eliminating the risk of warping, melting, or discoloration of materials.

- Thicker Materials: Water jet can cut much thicker materials than laser, allowing for the creation of substantial 3D floor designs.

- Reflective Materials: Water jets can easily cut reflective materials like mirrors or polished metals, which can be challenging for lasers.

- Delicate Materials: The cool cutting process of water jet is ideal for delicate materials that might be damaged by the heat of laser cutting.

- Multi-Layer Cutting: Water jet floor design allows for easy cutting of layered materials, perfect for creating complex inlays.

The Hydro-Lazer Advantage in Water Jet Floor Design

At Hydro-Lazer, we’ve honed our water jet floor design capabilities to offer unparalleled service to our clients.

Here’s what sets us apart:

- Cutting-Edge Technology: Our WSI 50 HP waterjet cutting systems represent the pinnacle of water jet technology.

- Large Format Capability: We can work on pieces up to 9 ft X 12 ft, allowing for the creation of large-scale floor designs.

- Expert Design Services: Our team can work from hand sketches or CAD drawings, using advanced software to render complex designs.

- Material Expertise: With over 30 years of experience, we understand how different materials behave under water jet cutting, ensuring optimal results.

- Custom Solutions: We tailor our services to meet the specific needs of each project, from small residential inlays to large commercial floor designs.

Water Jet Floor Design Applications

The versatility of water jet floor design opens up a world of possibilities.

Here are some popular applications:

- Waterjet Medallions: Creating stunning centerpieces for lobbies or entryways.

- Natural Stone Inlays: Combining different types of stone for unique patterns.

- Tile Mosaics: Cutting intricate shapes from various tile materials for detailed mosaics.

- Logo Inlays: Incorporating company logos or branding elements into flooring.

- Themed Designs: Creating floor designs that reflect a space’s theme or purpose.

Case Studies

To illustrate the power of water jet floor design, let’s look at a couple of real-world examples:

- Luxury Hotel Lobby: We created a 20-foot diameter medallion for a high-end hotel lobby, combining marble, granite, and brass inlays. The intricate design featured the hotel’s logo surrounded by a classical Greek key pattern. The precision of our water jet technology allowed for seamless integration of the different materials, creating a stunning first impression for hotel guests.

- Corporate Headquarters: For a tech company’s new headquarters, we designed and cut a series of floor inlays that represented the company’s journey. Starting from the entrance with simple circuit board patterns, the design evolved through the building, culminating in a complex, abstract representation of digital networks in the main conference room. The ability of to work with multiple materials – including stone, metal, and resilient flooring – was crucial in bringing this concept to life.

Choosing for Your Project

When considering water jet floor design for your project, here are some factors to keep in mind:

- Material Choice: Water jet is ideal for a wide range of materials, especially when combining different types.

- Design Complexity: If your design involves intricate patterns or very fine details, water jet offers superior precision.

- Thickness: For designs involving thicker materials or 3D elements, water jet is often the only viable option.

- Heat Sensitivity: If your chosen materials are sensitive to heat, water jet is the safer choice.

- Project Scale: For large-scale projects, water jet’s ability to handle big pieces can be a significant advantage.

The Future of Water Jet Floor Design

As technology continues to advance, we anticipate even more exciting developments.

From increased cutting speeds to even greater precision, the future looks bright for this versatile technology.

At Hydro-Lazer, we’re committed to staying at the forefront of water jet floor design innovation.

We continually invest in the latest equipment and training to ensure we can meet the evolving needs of designers and architects pushing the boundaries of floor design.

Are you ready to explore the possibilities of water jet floor design for your next project?

Whether you’re a designer looking to create a stunning centerpiece or an architect planning a large-scale commercial installation, Hydro-Lazer is here to help.

Contact us today to discuss how our services can bring your vision to life.

Let’s create flooring that doesn’t just cover ground, but breaks new ground in design and innovation.