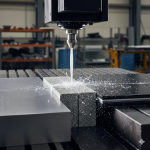

Modern plastic components demand what traditional cutting methods simply cannot deliver. Heat distortion, tool wear, and design limitations have long hindered the creativity and performance required in today’s fast-paced manufacturing environments. That’s where Hydro-Lazer’s plastic cutting services step in—offering a revolutionary shift in how polymers are processed, prototyped, and produced.

Using advanced waterjet technology, Hydro-Lazer unlocks unprecedented precision, clean edge quality, and material versatility—all without compromising the integrity of the plastic. Whether you’re an engineer looking to push the boundaries of what’s manufacturable or a production manager in need of scalable solutions, this is the new standard in polymer fabrication.

Why Waterjet Wins: The Core Advantage Behind Hydro-Lazer’s Plastic Cutting Services

Plastic cutting services have evolved. With Hydro-Lazer’s high-pressure waterjet systems, we’re not just slicing material; we’re optimizing every cut to maximize performance, reduce waste, and accelerate production timelines.

Here’s what sets our method apart:

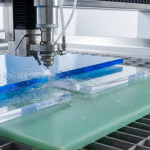

- No Heat-Affected Zone (HAZ): Plastic remains dimensionally stable, avoiding warping or microcracking.

- Edge Quality Excellence: Cuts are smooth, burr-free, and often require no secondary finishing.

- Design Freedom: Intricate patterns, internal cutouts, and tight curves are easy—no tooling required.

- Versatile Thickness Handling: From ultra-thin films to 2-inch thick polymers, we’ve got it covered.

- Material Preservation: Waterjet cutting doesn’t compromise molecular structure, essential for high-performance applications.

Simply put, Hydro-Lazer’s plastic cutting services redefine what’s possible.

Material Mastery Matrix: Polymer Expertise in Action

We don’t just cut plastic—we understand it. Hydro-Lazer brings a deep command of the polymer spectrum, allowing us to tailor our plastic cutting services to the specific behavior, hardness, and sensitivity of each material type.

Engineering Plastics

ABS, Polycarbonate, Nylon, PEEK

These tough, impact-resistant polymers demand precision. We deliver performance-ready parts that fit tight tolerances without internal stress or post-processing needs.

Commodity Plastics

PE (Polyethylene), PP (Polypropylene), PVC

Our waterjet process offers cost-effective, clean cuts perfect for high-volume runs, signage, packaging inserts, and structural applications.

High-Performance Polymers

PTFE, POM, Acrylics, Specialty Blends

No melting. No smearing. Just pure dimensional accuracy and consistent edge quality for the most demanding environments.

Composite Materials

Fiber-Reinforced Plastics, Hybrids, Laminates

Layered and mixed materials are no match for our controlled, cold-cutting technique. Maintain fiber alignment and structural integrity with every cut.

This is where plastic cutting services meet real polymer intelligence—and Hydro-Lazer leads the charge.

Application-Driven Solutions: Built Around Your Manufacturing Challenges

We don’t believe in generic solutions. Hydro-Lazer’s plastic cutting services are designed around your specific pain points.

- Tight Tolerance Requirements: Perfect-fit components that are assembly-ready out of the box.

- Complex Geometries: Internal voids, intricate mesh cuts, and layered designs—all cut cleanly and accurately.

- Prototype to Production: Rapid iteration with seamless scaling. Your design-to-market timeline just got faster.

- Custom Specs: Whether it’s aerospace-grade materials or FDA-approved plastics, we align with your compliance needs and goals.

You bring the challenge—we bring the solution.

The Hydro-Lazer Difference: Service Excellence You Can Rely On

Precision cutting is only part of the equation. Hydro-Lazer offers a complete plastic cutting services experience with:

- Rapid Response System: Fast quotes, fast production, and expedited turnaround when you need it most.

- Quality Assurance Protocol: Every part inspected, every job backed by our satisfaction guarantee.

- Collaborative Engineering: Not sure which polymer is right for the job? We guide you from selection to execution.

- Scalable Solutions: From one-off prototypes to full production runs—grow with confidence.

We’re not just a service provider. We’re your long-term partner in polymer precision.

Innovation in Plastic Processing: Pushing the Industry Forward

Hydro-Lazer is committed to constant improvement. Our plastic cutting services continue to evolve through:

- Cutting Parameter Optimization: Material-specific programs that ensure efficiency and consistency.

- Waste Reduction: Strategic nesting and intelligent routing to minimize scrap and cost.

- Surface Finish Control: Choose the texture or finish that fits your end-use—no post-processing required.

- Eco-Friendly Processing: No fumes, minimal waste, clean water recirculation. It’s smart, sustainable manufacturing.

Let’s Get Started: From Concept to Cut

Hydro-Lazer makes onboarding easy:

- Project Assessment: Send us your CAD files or sketches. We’ll align with your goals and specs.

- Material Guidance: We’ll help you select the right polymer for strength, function, and budget.

- Prototype Development: Test ideas quickly. Iterate without delay.

- Production Partnership: When it’s time to scale, we’re ready to grow with you.

From idea to implementation, our plastic cutting services are built for manufacturers who demand more.

Hydro-Lazer is where water meets precision—and plastics meet possibility. Let’s cut through the noise. Let’s create something better.