As manufacturing demands expand and materials diversify, production methods must evolve to maintain precision and efficiency. Traditional laser and plasma cutting are reliable, but modern projects often require a solution that preserves material integrity while handling complex designs. Industrial waterjet cutting provides cold cutting with consistent tolerances across metals, composites, and specialty materials, avoiding heat-related distortions.

Waterjet technology produces clean edges, reduces post-processing, and minimizes material waste. Its flexibility allows multiple material types and thicknesses to be processed in a single workflow. Streamlined operations improve accuracy, support faster production cycles, and enhance overall project outcomes.

Hydro-Lazer’s experience shows waterjet systems improve edge quality, material handling, and operational efficiency. Production teams and engineers benefit from clear technical insights and workflow consistency. This method delivers a dependable, precise, and adaptable solution for complex industrial projects.

Material Versatility Beyond Laser Limitations

Industrial waterjet cutting handles metals, composites, stone, and specialty materials with consistent precision. Unlike laser systems, which can slow or produce inconsistent cuts on reflective surfaces, or plasma systems, which may reduce accuracy on thick metals, waterjet cutting maintains tight tolerances regardless of material type. Thicknesses from thin sheets up to six inches can be processed in a single pass, while multiple materials can be cut together, reducing setup time and handling errors.

For example, a production run combining 1/4-inch aluminum and 1/2-inch stainless steel can be completed on one waterjet setup with predictable dimensions. Distortion is minimized, eliminating the need for secondary finishing and rework. Manufacturers benefit from higher throughput, smoother workflows, and improved operational reliability.

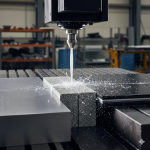

Cold Cutting Preserves Material Properties

Cold waterjet cutting supports material integrity, maintaining strength and preventing deformation in sensitive components. High-pressure abrasive streams deliver precise results while keeping thermal influence to a minimum. Projects achieve consistent tolerances and structural reliability, reducing corrective work and production delays.

Precision industries, such as aerospace, benefit from predictable mechanical properties and stable parts. Heat-free cutting reduces post-processing requirements and improves throughput. Reliable performance enhances operational efficiency and lowers manufacturing costs.

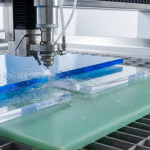

Consistent Edge Quality Reduces Finishing Time

Edge quality plays a critical role in manufacturing efficiency. Traditional methods like laser or plasma cutting can create micro-slag or uneven surfaces, requiring additional labor and time for finishing. Clean edges streamline workflow and reduce unnecessary handling.

Waterjet cutting delivers precise edges with tolerances around ±0.003 inches. Parts are often ready for assembly immediately, eliminating extra processing steps. Uniform edge quality ensures consistent performance across multiple materials and batches.

Reducing finishing time increases production speed and resource efficiency. Fewer adjustments and touch-ups lower labor costs while maintaining quality. Reliable cutting methods create predictable outcomes for every project.

Operational Efficiency Supports Productivity

Production efficiency is influenced by setup time, consumables, maintenance, and programming complexity. Laser systems require frequent cleaning and calibration, especially for reflective materials. Plasma systems experience wear on consumables, which can impact production schedules.

Waterjet systems use predictable consumables with maintenance cycles extending over weeks. Job changeovers are simple, and programming adjustments for material type or thickness are minimal. Metrics from Hydro-Lazer clients show that throughput remains consistent across different materials and thicknesses while maintaining tight tolerances. Production teams can achieve high utilization rates and reduce operational disruptions.

Evaluating Waterjet for Manufacturing Operations

Industrial waterjet adoption improves operational flexibility and precision. Reflective metals, composites, and thick materials require cutting methods that maintain tolerances and structural integrity. Waterjet systems reduce heat exposure, minimizing material distortion and supporting high-quality output.

Production planning benefits from the ability to cut multiple materials in a single cycle. Shorter lead times and reduced secondary processing improve overall efficiency. Consistent, accurate parts help manufacturers meet project schedules and client expectations.

Cost evaluation encompasses consumables, labor, and finishing needs, offering a complete view of return on investment. This ensures informed decisions that align technology choices with business objectives. Waterjet integration contributes to both performance and operational control.

Implementation Considerations

Transitioning to waterjet cutting involves planning for workflow integration, equipment placement, and operator training. Waterjet systems can complement existing laser or plasma processes or become the primary method for certain material types. Operators familiar with laser programming can adapt to waterjet systems with minimal adjustment due to similar CNC control structures.

Trial cutting programs with Hydro-Lazer provide measurable insights into cutting speed, part quality, and operational cost. These evaluations ensure alignment with production needs, enabling facilities to optimize workflows and achieve consistent results across multiple materials.

Unlock Precision and Efficiency with Hydro-Lazer Waterjet Cutting

Industrial waterjet cutting brings manufacturing operations unmatched versatility, precise results, and efficient workflows. It preserves material integrity, ensures smooth edge quality, and minimizes additional processing steps. These capabilities streamline production planning while supporting consistent, cost-effective operations.

Hydro-Lazer offers expert consultation and trial cutting services that guide manufacturers in exploring the best solutions for their materials, production volumes, and quality requirements. Each trial provides valuable insights to optimize processes and achieve reliable outcomes. Collaborating with Hydro-Lazer opens opportunities to enhance productivity and meet high standards with confidence.

Experience the benefits of waterjet technology by connecting with Hydro-Lazer for a personalized consultation or demonstration. Manufacturers can see firsthand how precision cutting integrates seamlessly into their workflows. Taking this step ensures operations are efficient, quality-driven, and prepared for future growth. Get Professional Waterjet Cutting for Any Material — Request Your Consultation!