When production lines depend on precise plastic components delivered on schedule, small inefficiencies quickly escalate into major bottlenecks. From aerospace to medical devices, today’s manufacturers can’t afford delays, poor tolerances, or material waste. This is why plastic cutting services have shifted from being a back-end support task to a mission-critical driver of efficiency, reliability, and scalability.

Hydro-Lazer understands that every plant manager and production engineer works under constant pressure: throughput must rise, quality must hold, and costs must stay competitive. That’s where industrial waterjet cutting steps in—not as a convenience, but as a production advantage.

Thermoplastics: Precision Cutting for Every Category

High-Performance Engineering Plastics

Materials like PEEK, PEI, and PPS demand extreme precision. Their role in aerospace and medical devices means tolerances aren’t negotiable. Hydro-Lazer’s plastic cutting services preserve the high-temperature resistance and chemical durability of these materials while maintaining clean, tight dimensions across batches.

Industrial-Grade Polymers

For mechanical components, Nylon, Delrin, and HDPE must perform under constant wear. Our waterjet technology enables high-volume processing with dimensional stability, ensuring every part meets spec without unnecessary finishing.

Specialty Thermoplastics

PTFE, antistatic, and food-grade materials bring specialized performance requirements. Hydro-Lazer’s experience ensures compliance with both safety and industry regulations while optimizing cut quality to avoid costly rework.

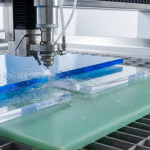

Commodity Plastics at Scale

ABS, Polycarbonate, and Acrylic still dominate mass production runs. By leveraging waterjet precision, Hydro-Lazer delivers consistent quality, cost efficiency, and minimal waste for large-scale projects.

Mastering Composite Material Processing

Industrial-scale plastic cutting services don’t stop at thermoplastics. Composites require advanced strategies to avoid delamination or structural compromise. Hydro-Lazer’s waterjet systems are engineered to handle:

- Fiber-Reinforced Composites: Carbon fiber and glass fiber parts for aerospace and automotive sectors, cut without damaging fiber orientation.

- Layered Systems: Multi-layer panels and sandwich structures where bonding integrity must be preserved.

- Specialized Applications: Phenolic and epoxy composites designed for insulation or high-strength performance.

- Production-Scale Panels: Large sheets cut with consistent edge quality, optimized nesting, and minimal material loss.

Production Excellence: Scaling with Industrial Demands

Hydro-Lazer designs plastic cutting services around industrial realities—where one-off accuracy isn’t enough. What matters is repeatability, speed, and production alignment.

- High-Volume Manufacturing: From prototypes to full production, scalable solutions minimize waste and ensure scheduling alignment.

- Precision & Repeatability: Every cut holds to tight tolerances with statistical process control backing up results.

- Efficiency Optimization: Batch processing and quick changeovers cut downtime and increase throughput.

- Quality Integration: ISO-certified processes and first article inspections assure confidence across entire production runs.

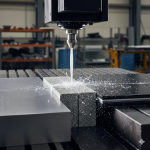

Why Waterjet Wins in Manufacturing

Waterjet cutting technology is more than a process—it’s a strategic production tool. Hydro-Lazer’s systems provide:

- Cold Cutting Advantage: Eliminates heat-affected zones, preserving integrity of plastics and composites.

- Versatility in Thickness: From thin films to thick plates, precision holds across every cut.

- Complex Geometry Capability: Sharp corners, internal cutouts, and multi-axis cuts without tooling constraints.

- Superior Edge Quality: Smooth edges reduce finishing operations and deliver parts assembly-ready.

Every one of these advantages adds up to lower costs, faster turnarounds, and higher confidence for manufacturers managing complex supply chains.

Industrial Service Excellence: More than Cutting

Hydro-Lazer isn’t just about delivering parts—it’s about supporting production goals. Our plastic cutting services include:

- Production Planning: Aligning with manufacturing timelines, capacity planning, and inventory support.

- Technical Consultation: Guiding material selection, design-for-manufacturing, and cost optimization.

- Quality Programs: Documented inspection, certification, and process monitoring.

- Responsive Support: Rush orders, flexible scheduling, and long-term reliability as a manufacturing partner.

Hydro-Lazer: Your Industrial Cutting Partner

At the end of the day, industrial manufacturing is a race against time, cost, and competition. Precision cutting isn’t just a capability—it’s a lever for production efficiency. Hydro-Lazer positions itself as more than a vendor; we are an industrial partner offering plastic cutting services built on performance, reliability, and scalability.

- Manufacturing Expertise: We understand production pressures and engineering demands.

- Quality Consistency: Every run meets tolerances without exceptions.

- Efficiency Gains: Our processes streamline throughput and reduce waste.

- Ongoing Support: Consultation and continuous process optimization ensure long-term competitive advantage.

When the stakes are high and production schedules are unforgiving, Hydro-Lazer transforms cutting challenges into opportunities for growth. That’s the industrial promise of waterjet technology—and the measurable value of trusted plastic cutting services.