There’s something quietly revolutionary about how the cleanest, most precise cuts in today’s toughest materials are made—with nothing but water and grit. Sounds simple? It’s not. But this is the new normal for engineers, designers, manufacturers, and architects pushing the boundaries of what materials can do. The secret? Advanced waterjet cutting solutions, and Hydro-Lazer is the name you need to know.

Welcome to the age of cold-cutting innovation. Long gone are the days of relying solely on saws, lasers, or plasma cutters for complex jobs. As industries evolve and demand cleaner edges, tighter tolerances, and safer production processes, abrasive waterjet cutting has stepped into the spotlight. And leading that charge is Hydro-Lazer, a veteran in the game with over 30 years of precision cutting excellence under its belt.

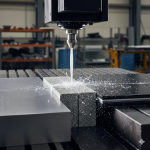

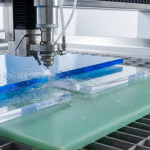

The Science Behind Abrasive Waterjet Cutting

Let’s get into what sets this cutting method apart. Abrasive waterjet cutting uses a high-pressure stream of water, up to 90,000 psi, mixed with fine abrasive particles like garnet. This stream travels at near-supersonic speeds, slicing through the hardest materials with jaw-dropping accuracy.

Unlike traditional methods that generate heat and distort materials, waterjet technology stays cool. That means no heat-affected zones, no warping, and no change to the material’s molecular structure. For professionals who care about edge quality and structural integrity, that’s a game changer.

While pure waterjet cutting works great on softer materials like foam or rubber, it’s the abrasive waterjet that unlocks the power to shape metals, stone, ceramics, and even bulletproof glass. It’s the most versatile, non-thermal cutting process on the market today.

Why Waterjet Cutting Solutions Are Dominating Modern Manufacturing

Waterjet cutting solutions like those at Hydro-Lazer are built to serve industries where precision isn’t just a goal—it’s a necessity. Here’s why they’re winning across the board:

- No Heat Damage: Preserve the integrity of steel, glass, and composites without burns, warps, or micro-fractures.

- Extreme Material Versatility: From titanium to granite, Hydro-Lazer handles it all. Metal, stone, glass, ceramic—you name it.

- Precision You Can See: Need tight tolerances or intricate patterns? This is where waterjet cutting truly shines.

- Environmentally Conscious: No toxic fumes, low waste output, and even the water is recyclable.

- Cleaner Cuts, Smoother Edges: Less post-processing means faster turnaround and lower costs.

Hydro-Lazer’s Cutting-Edge Capabilities

This isn’t just any shop with a jet and a table. Hydro-Lazer operates a fleet of CNC-controlled cutting systems, meticulously dialed in for complex and custom jobs. Working from your CAD files or collaborating directly with your team, their experts optimize everything—speed, pressure, abrasive type—tailored to your specific materials and project needs.

Whether you’re prototyping a single component or scaling up for full production runs, Hydro-Lazer’s waterjet cutting solutions are engineered for both flexibility and repeatability. This is not about one-size-fits-all. It’s about high-performance precision at any scale.

Industry Applications That Demand Perfection

Hydro-Lazer doesn’t just cut parts—it enables possibilities across industries:

- Aerospace & Defense: When tolerances are tight and safety is paramount, their solutions excel.

- Architecture & Interior Design: Custom inlays, intricate panels, or brand-forward metal logos? Done.

- Automotive & Industrial Manufacturing: Brackets, casings, gears, you name it—delivered fast and accurately.

- Signage & Art: Metal and stone become expressive, polished forms in the hands of Hydro-Lazer’s team.

Every cut reflects Hydro-Lazer’s deep commitment to precision, quality, and durability.

Why Hydro-Lazer Is the Partner You’ve Been Looking For

Three decades in, Hydro-Lazer continues to lead the charge in waterjet cutting solutions across North America. It’s not just about the machines (though theirs are top-tier); it’s about their people, their process, and their promise to deliver unmatched quality and speed.

Responsive communication. Streamlined project management. Nationwide delivery. And a relentless focus on quality control. If you’re looking for a partner who understands both the art and science of cutting, Hydro-Lazer delivers.

Shaping the Future with Hydro-Lazer’s Waterjet Expertise

In a world where tolerances are tighter and materials more demanding, abrasive waterjet cutting is the solution modern industries turn to. It’s precise, versatile, eco-conscious, and repeatable. And with Hydro-Lazer, it’s also reliable, fast, and tailored to your goals.

So, whether you’re designing a complex aerospace component or a stunning architectural detail, Hydro-Lazer’s waterjet cutting solutions will help you bring your vision to life flawlessly.

Have a project that requires flawless cuts and fast turnaround?

Contact Hydro-Lazer today to learn how our abrasive waterjet solutions can bring your designs to life.