If you’re in Pennsylvania—whether in the heart of Philadelphia’s aerospace manufacturing hub or deep within Pittsburgh’s architectural design scene—you already know the challenge: ceramic is unforgiving. It’s brittle, heat-sensitive, and when it comes to intricate designs or technical tolerances, even a tenth of a millimeter off can wreck an entire batch.

That’s exactly what a defense subcontractor near Philadelphia faced. They needed precise cuts for aerospace-grade ceramic components—thin, dense, and with no margin for error. Their previous provider left burn marks and hairline fractures. Then they found Hydro-Lazer.

Hydro-Lazer took the job and redefined the expectations of ceramic waterjet cutting services across Pennsylvania.

Why Hydro-Lazer Wins: Precision at the Edge of Innovation

Let’s talk about tech.

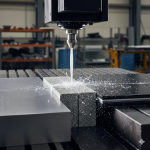

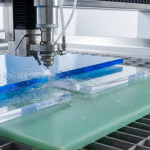

Hydro-Lazer operates with waterjet systems capable of cutting ceramic at pressures up to 90,000 PSI with precision tolerances as tight as ±0.001 inch. Compare that to traditional blade cutting (inconsistent, high fracture rates) or laser cutting (excessive thermal stress), and the difference is night and day. Unlike heat-based systems, waterjet cutting preserves the structural integrity of ceramic—no burns, no cracks, no compromise.

And this isn’t plug-and-play gear. Hydro-Lazer has made strategic technology upgrades over the past decade, evolving their capabilities with every material-specific demand. Their ceramic-focused innovations—abrasive garnet calibration, nozzle refinement, flow control systems—place them ahead of any other ceramic waterjet cutting services provider in Pennsylvania.

“We’ve tested everyone,” says a lead engineer from a Pittsburgh-based electric utility. “Hydro-Lazer delivered smoother edges, tighter specs, and better communication than any shop we’ve used in 20 years.”

Across Pennsylvania: Hydro-Lazer’s Ceramic Portfolio in Action

From Erie to Allentown, Hydro-Lazer’s impact on Pennsylvania ceramics is everywhere.

- Philadelphia aerospace firms now rely on Hydro-Lazer to cut zirconia and alumina ceramics for high-temperature applications.

- Pittsburgh’s commercial architects trust them to waterjet custom ceramic tiles for high-end retail, luxury hotels, and public art installations.

- Central PA energy providers use their services for cutting ceramic insulators and dielectrics—delicate parts that require no thermal warping.

- Even independent artists and designers across the state praise Hydro-Lazer for enabling complex ceramic shapes that simply weren’t possible before.

This is about skill and solving ceramic problems that others couldn’t. One Bethlehem contractor noted Hydro-Lazer saved his project timeline after two other cutting shops failed. That’s the difference real expertise makes.

The Hydro-Lazer Experience: Beyond the Cut

What keeps clients coming back? It’s the machines and the method.

From first call to final cut, Hydro-Lazer’s process is engineered for professionals who value clarity and quality.

- Project transparency: Every project comes with detailed updates, tolerance confirmation, and a collaborative design consultation.

- Quality control: Every ceramic piece goes through multi-stage inspections with digital micrometer verification. If something’s even slightly off, it doesn’t ship.

- Logistics leadership: Whether it’s same-day delivery to a Harrisburg factory or custom-packaged ceramic art headed to Scranton, logistics is treated like part of the product.

As one Lancaster designer said, “It’s the first time I’ve ever felt like the cutting service was part of my team.”

Why Local Mastery Matters in Ceramic Cutting

Hydro-Lazer is in Pennsylvania and understand Pennsylvania.

Their teams know the state’s ceramic standards, from Philly’s commercial fire-rating codes to Pittsburgh’s cold-weather tile expansion factors. They’re embedded in local supply chains, which means faster sourcing, quicker turnarounds, and on-the-ground support.

And when a rush job comes in from a York manufacturing plant or a Reading-based university lab? They don’t blink. Their regional presence makes urgent turnaround possible—no shipping delays, no supplier confusion.

That’s the edge only a true Pennsylvania-based ceramic waterjet cutting services provider can offer.

Built for the Future: Hydro-Lazer’s Ceramic Innovation Commitment

Hydro-Lazer is never content to stay static.

- They were the first in the state to adopt multi-axis ceramic waterjet cutting.

- They’ve launched in-house R&D to refine abrasive mixtures specifically for ceramic.

- They’ve invested in sustainability—closed-loop water systems that reduce waste and increase precision.

It’s why industry organizations have recognized Hydro-Lazer’s role in shaping the future of ceramic waterjet cutting services—and why clients keep returning as needs evolve.

Results That Measure Up

Here’s the bottom line:

- 98.7% client retention rate in Pennsylvania over five years

- Average project completion time 22% faster than competitors

- Less than 0.3% rework rate on ceramic jobs

- Service reach across all major PA counties, including remote industrial zones

And the proof is in the partnerships: dozens of PA businesses now list Hydro-Lazer as their exclusive ceramic cutting provider.

Ready to Cut Smarter?

If you’ve seen your ceramic projects fail because of rough cuts, cracks, or missed deadlines—maybe it’s time to switch to the experts trusted from Philadelphia to Pittsburgh. Hydro-Lazer cut ceramic and craft precision, deliver confidence, and support innovation statewide.

Hydro-Lazer. Pennsylvania’s leader in ceramic waterjet cutting services.

If you’ve worked with Hydro-Lazer and loved the results, let others know. Your reviews help more Pennsylvania businesses find the right cutting partner.