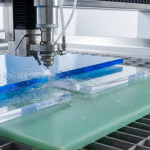

In today’s fast-moving, detail-driven world, plastic cutting services are no longer a luxury—they’re a necessity. Whether you’re fabricating automotive components, signage panels, medical-grade plastic parts, or designing sleek retail displays, precision is the name of the game. And if you’re searching for accuracy, customization, and reliability in plastic fabrication, Hydro-Lazer delivers. Their cutting-edge waterjet technology offers something that traditional and laser cutting simply can’t match—flawless, heat-free results across a variety of plastic materials.

Let’s walk through what makes Hydro-Lazer’s plastic cutting services the gold standard for engineers, designers, and manufacturers who need exactness without compromise.

Why Precision in Plastic Cutting Is Non-Negotiable

Plastics are incredibly versatile. You’ll find them in everything from consumer electronics to architectural signage to surgical equipment. But not all plastics are created equal, and neither are the cuts that shape them. A single slip or distortion can derail a project’s structural integrity or appearance.

That’s why plastic cutting services have to deliver clean, precision cuts that meet tight tolerances. Even small defects can affect how components fit, function, and hold up over time. That’s where Hydro-Lazer stands out for getting the job done and getting it done right the first time.

Their high-powered waterjet cutting systems handle everything from single sheets of acrylic to multi-layered polycarbonate with incredible accuracy. No melting, no warping, no second-guessing.

What Plastics Can Be Cut?

Hydro-Lazer’s waterjet systems are versatile enough to work with a wide range of plastic materials. Whether you need to cut acrylic signage or industrial-grade Delrin parts, they’ve got you covered:

- Acrylic (Plexiglass) – Perfect for clean, crystal-clear edges in displays

- Polycarbonate – Durable and strong, great for impact-resistant panels

- PVC – Common in construction and signage

- HDPE – Used for industrial gaskets and machine parts

- Nylon & Delrin – Ideal for gears and moving components

- ABS & Thermoplastics – Flexible options for prototyping and molding

These materials are sliced, precision-cut using cold waterjet streams that prevent heat distortion, discoloration, or edge fraying.

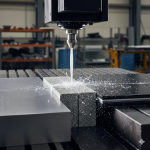

Cutting Methods: Why Waterjet Wins

There’s more than one way to slice a plastic sheet, but not all methods are created equal:

- Traditional Cutting (Saws, Blades): Good for rough prototypes, but you’ll often deal with chips, cracking, and the need for post-processing.

- Laser Cutting: Ideal for detailed patterns but often causes heat-affected zones, which can discolor or melt softer plastics like HDPE or acrylic.

- Waterjet Cutting – Hydro-Lazer’s Signature Service

- Zero heat = no risk of melting or stress marks

- Maintains tight tolerances on thick or layered plastics

- Eco-friendly with minimal waste

- Cuts clean—no sanding or finishing needed

- Handles intricate designs just as easily as structural panels

In short, it offers precision and performance with none of the trade-offs.

Who Uses Plastic Cutting Services?

From massive production runs to one-off prototypes, businesses across industries rely on accurate plastic cutting every day:

- Signage and Branding – Logos, lettering, and backlit acrylics

- Automotive & Aerospace – Interior panels, protective casings

- Consumer Products – Packaging trays, plastic rods, display units

- Medical Equipment – Housing for electronics, ergonomic tools

- Industrial Applications – Custom-cut plastic sheets and gaskets

Hydro-Lazer helps each of these sectors achieve efficiency and excellence, with plastic parts that fit perfectly, look polished, and perform reliably.

Real Projects, Real Results

Hydro-Lazer’s portfolio speaks for itself. They’ve produced:

- Point-of-sale acrylic displays that pop on retail floors

- Machine gaskets from HDPE that meet extreme durability standards

- Custom signage panels with detailed contours and vibrant finishes

- Protective covers and shields for sensitive electronics

Each project highlights their ability to adapt to different materials, scales, and designs—all with surgical-level precision.

Choosing the Right Cutting Partner

Not all plastic cutting services providers are the same. Here’s what to look for:

- Experience with a variety of plastic materials

- Advanced cutting equipment like Hydro-Lazer’s waterjet system

- Ability to meet tight tolerances

- Flexible turnaround times for prototyping or production

- Commitment to quality assurance at every stage

Hydro-Lazer checks every box—and then some. Their team works side-by-side with clients to understand specs, customize outputs, and guarantee a seamless cutting process from design to delivery.

Ready to Elevate Your Next Project?

If your current supplier is leaving rough edges or delays on the table, it’s time for an upgrade. Hydro-Lazer’s plastic cutting services combine cutting-edge technology with unmatched craftsmanship, delivering flawless results that save time, reduce waste, and boost product performance.

Contact us today to get a quote or talk through your next custom cutting project. Let Hydro-Lazer show you why waterjet plastic cutting is the smarter, sharper solution.