Projects involving aluminum brackets, marble inlays, or ceramic tiles often require multiple vendors, timelines, and quality checks. Each material responds differently to cutting techniques, making consistency and precision essential for fabricators and project managers. Coordinating equipment, tolerances, and schedules can be complex, and streamlining the process supports smoother project execution.

Custom waterjet services simplify this challenge by handling metals, stone, ceramics, and specialty materials in a single workflow. Using one versatile cutting method reduces coordination demands while maintaining consistent quality across all materials. This approach allows projects to move forward confidently, with precision and efficiency at every stage.

Waterjet technology preserves the unique properties of each material while accommodating diverse fabrication needs. Fabricators benefit from fewer process steps, reduced waste, and reliable results that meet exacting specifications. By integrating multiple materials into one controlled workflow, custom waterjet services offer a practical, dependable solution for complex projects.

How Custom Waterjet Services Handle Every Material in Your Project

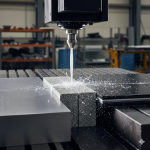

Waterjet cutting utilizes high-pressure water and abrasive particles to deliver highly accurate cuts across metals, stone, ceramics, and specialty materials. The cold cutting process preserves the integrity of each material, ensuring clean edges without thermal distortion.

Designers and architects can specify intricate combinations of materials, achieving complex shapes and patterns without compromising quality. Manufacturing engineers benefit from a CNC-controlled system that adapts to diverse materials while maintaining tight tolerances.

Operational efficiency is enhanced by seamless adjustments in water pressure and abrasive feed, allowing smooth transitions between materials. Consistent precision reduces material handling and preparation, improving workflow and ensuring reliable outcomes on every project.

Material-Specific Waterjet Cutting Capabilities

Metal Waterjet Cutting: Aluminum, Stainless Steel, and Titanium

Custom waterjet services enable accurate cutting of aluminum, stainless steel, titanium, and steel alloys for industrial and commercial applications. The process preserves material properties while handling both thin sheets and thick plates efficiently. Components such as brackets, fixtures, and prototypes are produced reliably with smooth edges and consistent dimensions.

Stone Waterjet Cutting: Marble, Granite, and Specialty Stone

Stone materials are cut with precision, maintaining surface integrity and avoiding chipping or cracking. Waterjet technology supports custom countertops, flooring inlays, and complex architectural patterns with narrow kerfs that minimize waste. Both thin and thick slabs are processed accurately, ensuring reliable results across diverse stone applications.

Ceramic and Tile Waterjet Cutting for Precision Installations

Ceramic and tile materials are cut with precision, maintaining structural integrity and surface glaze. Clean, accurate edges support custom layouts, mosaic designs, and flooring inlays for both residential and commercial projects. Compatibility with soft and hard-fired tiles ensures components align perfectly for precise and reliable installation.

Slate Tile and Roofing Material Waterjet Cutting

Custom waterjet cutting enables the precise shaping of slate tiles for roofing, flooring, and architectural applications. The process maintains material integrity while adapting to natural variations in thickness, ensuring consistent quality across all pieces. Reliable cutting reduces waste and supports efficient production for projects requiring both durability and exact dimensions.

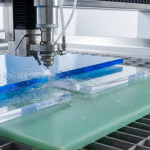

Specialty and Composite Material Waterjet Cutting

Custom waterjet services handle a wide range of specialty materials such as plastics, rubber, acrylics, gaskets, laminated composites, and glass with precision and care. Each cut preserves the material’s quality, avoiding warping, delamination, or compression, making it ideal for prototypes, seals, and layered assemblies. This process allows designers to explore multi-material projects with confidence, creating functional and visually precise components.

Operational Efficiency: Switching Materials Without Changing Equipment

Waterjet cutting provides an efficient workflow across metals, stone, ceramic, and specialty materials. The same nozzle assembly can transition seamlessly from one material to another with only minor adjustments to pressure and abrasive feed rates. CNC programming adapts to thickness and material characteristics automatically, maintaining consistent quality across every component.

This efficiency reduces project time, simplifies vendor coordination, and ensures uniform quality. A commercial project involving stainless steel trims, marble tiles, and ceramic accents can be completed as a single process. Multi-material projects progress smoothly, supporting timely delivery and precise assembly.

Custom Waterjet Cutting Adapts to Your Project’s Material Needs

Waterjet cutting adapts to diverse materials, enabling innovation and flexibility in product design. Hydro-Lazer delivers reliable expertise for standard and specialized materials, supporting efficient workflow management and technical consultation. Projects experience consistent precision, optimal edge quality, and repeatable performance across all material types.

Versatile material handling allows businesses to streamline production for complex assemblies and prototypes. The single-source solution reduces coordination challenges, ensuring projects progress smoothly from concept to completion. Strategic material management enhances operational efficiency and reduces potential delays in production schedules.

Discuss Your Multi-Material Project with Waterjet Cutting Experts

Waterjet cutting accommodates multiple materials, enabling streamlined production for metals, stone, ceramics, and specialty components. Hydro-Lazer offers a unified workflow and dedicated point of contact, reducing coordination time and increasing project efficiency. Consistent cutting precision ensures each fabrication meets rigorous quality standards.

Material consultations help define optimal combinations and process requirements for specific projects. Quotes are structured to support informed budgeting and planning. Flexible solutions adapt to complex designs, ensuring smooth execution across all stages of production.