Complex projects increasingly combine metals, stone, plastics, composites, glass, and wood to create functional and aesthetic advantages. Each material adds unique characteristics, and managing multiple fabrication processes can challenge even the most organized project teams. Hydro-Lazer’s abrasive waterjet cutting services provide a single process solution that addresses all solid materials, offering a consistent approach to cutting, precise results, and simplified project coordination.

Waterjet cutting allows project managers, general contractors, and design-build professionals to source multiple material needs from one fabricator, providing operational efficiency and a streamlined workflow across metals, stone, plastics, composites, wood, and glass. This consolidation approach helps ensure timelines remain consistent and quality remains uniform across all components.

Material Versatility with a Single Process

- Metals: Hydro-Lazer’s waterjet system handles aluminum, stainless steel, brass, copper, and tool steels in one process. It maintains edge precision and dimensional accuracy for both soft and hard metals.

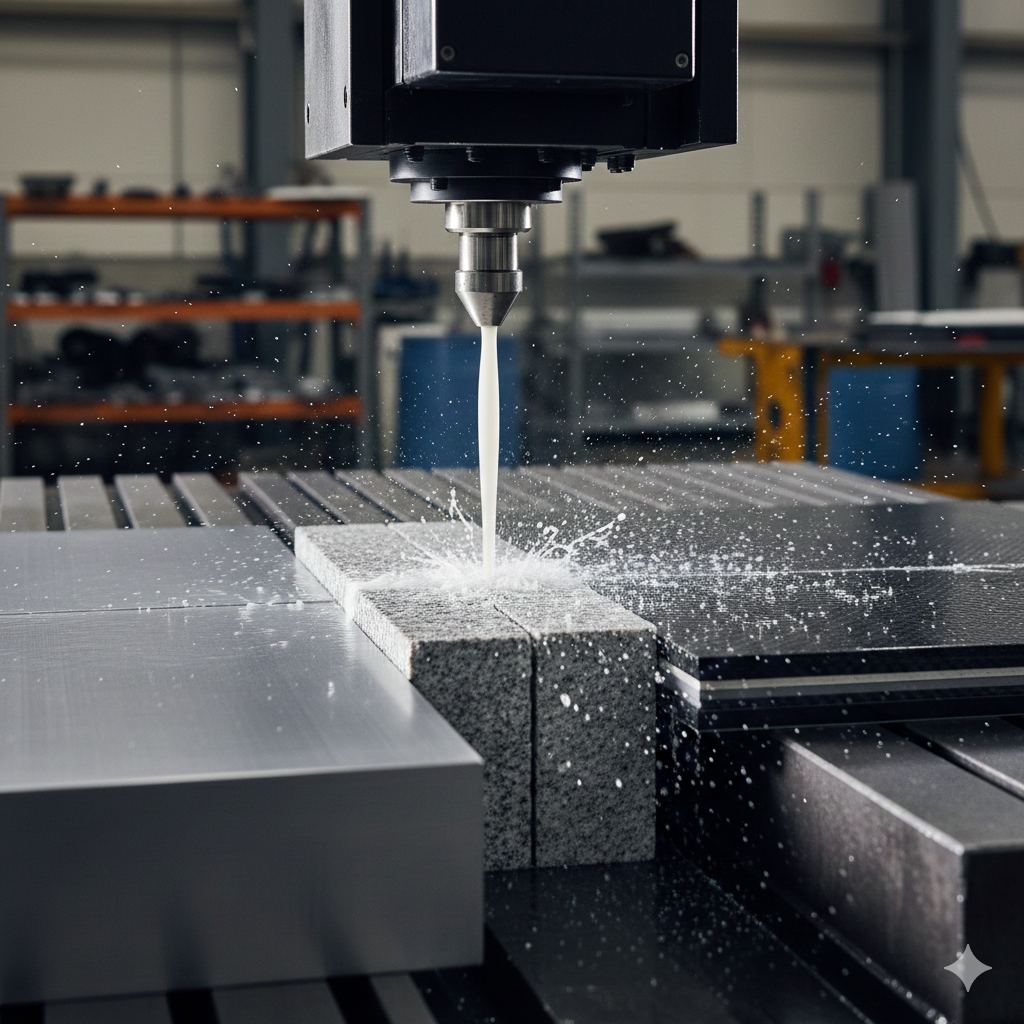

- Stone and Ceramics: Marble, granite, slate, porcelain, and ceramic tiles are cut cleanly without thermal effects. Cold cutting prevents cracks and maintains precise edges across all thicknesses.

- Plastics and Polymers: Materials such as acrylic, polycarbonate, HDPE, and PVC retain their form during cutting without warping. Uniform cutting across plastic and other materials simplifies assembly and supports accurate alignment with adjoining components.

- Composites and Engineered Materials: Carbon fiber, fiberglass, and laminated composites are cut efficiently with controlled erosion. Components from different materials can be produced together, ensuring consistent fit and finish across all project elements.

- Wood and Organic Materials: Rubber, gaskets, and dense woods can be processed with the same waterjet equipment used for metals and plastics. This single-source approach reduces coordination needs and ensures uniform quality for every part in multi-material assemblies.

- Glass: Precision glass cutting with waterjet technology ensures clean edges and consistent shapes. Integration with other materials occurs without alignment issues.

Efficiency Gains in Project Management

- Vendor Consolidation: Managing all cutting needs through Hydro-Lazer simplifies procurement, scheduling, and quality verification by reducing the complexity of working with multiple vendors.

- Timeline Compression: Waterjet processing allows multiple materials to be cut simultaneously, ensuring components arrive in sequence to maintain smooth project flow.

- Quality Consistency: Uniform cutting processes guarantee that all components meet the same dimensional and edge standards, minimizing adjustments during assembly.

- Design Flexibility: One cutting process accommodates all materials, making project modifications possible without impacting schedules or vendor agreements.

- Simplified Documentation: A single vendor streamlines specifications, quality agreements, and invoicing, reducing administrative overhead and simplifying record-keeping.

- Coordinated Delivery: Centralized delivery from one source reduces storage needs and supports efficient on-site workflows for faster installation.

Applications Where Multi-Material Projects Benefit

- Architectural Projects: Waterjet services ensure dimensional compatibility and uniform quality across steel, stone, glass, and composite elements for precise building assembly.

- Interior Design Projects: A single cutting service simplifies fabrication for interiors, ensuring metals, stone, plastics, and wood fit together seamlessly and maintain design cohesion.

- Signage and Wayfinding Systems: Single-source waterjet cutting guarantees precise alignment and high-quality results for multi-material signs including metal, acrylic, and stone components.

- Custom Fixtures and Displays: Waterjet cutting enables accurate prototype production and smooth transition to full-scale fabrication for retail displays, museum installations, and specialized furniture.

- Product Development: Using the same cutting method across metals, plastics, and composites accelerates prototyping and supports reliable material testing and iteration.

- Renovation and Retrofit Projects: Replacement components can be accurately cut from any material, maintaining consistent quality without needing additional vendors.

Practical Considerations for Implementation

- Project Planning: Coordinating cut specifications across all materials during design ensures consistent quality and efficient production.

- Communication Efficiency: Working with a single fabrication partner streamlines communication and allows proactive handling of material adjustments.

- Specification Development: Unified specifications for tolerances, edge finishes, and delivery conditions simplify documentation and set clear project expectations.

- Budget Predictability: Single-vendor relationships provide clearer cost expectations and reduce administrative complexity compared to managing multiple contractors.

- Problem Resolution: One point of contact enables quick resolution of adjustments or concerns, keeping the project on schedule without negotiating with multiple vendors.

Strategic Advantages for Multi-Material Projects

Hydro-Lazer’s abrasive waterjet cutting services combine multi-material capability with operational simplicity. Metals, stone, plastics, composites, wood, and glass can be cut with a single process, ensuring precision, quality, and coordination throughout a project. Teams benefit from streamlined vendor management, consistent quality, faster production timelines, simplified documentation, and unified delivery.

For projects where multiple materials are essential to design and functionality, Hydro-Lazer offers a single-source fabrication solution that enhances efficiency, supports design flexibility, and ensures dependable results.Contact Hydro-Lazer in Freeport, PA for abrasive waterjet cutting services for all project materials and experience the ease of single-process multi-material fabrication.