Abrasive waterjet cutting services have become the gold standard in industries where accuracy and versatility are paramount. Hydro-Lazer, a leader in high-precision cutting, provides these advanced solutions, delivering custom parts and sheet metal cut parts with unmatched detail and efficiency.

This article will delve into the mechanics, advantages, and application of abrasive waterjet cutting services, showing why this technology has revolutionized production runs, machine shops, and custom cutting services.

What Is Abrasive Waterjet Cutting?

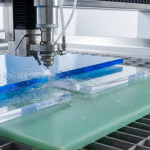

At its core, abrasive waterjet cutting is a high-precision technique that uses a jet of high-pressure water mixed with abrasive materials, typically garnet, to cut through a variety of hard and soft materials.

Unlike traditional cutting methods such as laser cutting, abrasive waterjet cutting services don’t involve heat, which prevents the formation of heat-affected zones (HAZ) that could compromise the material’s integrity. This makes it especially ideal for materials that are sensitive to thermal distortion, like metals, composites, and ceramics.

Hydro-Lazer’s approach to abrasive waterjet cutting ensures precision cuts that are both intricate and fast. It’s the go-to solution for industries looking for superior results without the drawbacks of other methods.

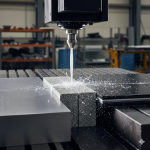

How Abrasive Waterjet Cutting Works

The process is both fascinating and efficient. First, water is pressurized up to 60,000 psi (pounds per square inch), creating a powerful jet capable of cutting through even the toughest materials. The water is mixed with an abrasive substance that enhances the cutting power, allowing Hydro-Lazer to cut through thick sheet metal, stone, plastics, glass, and more.

What makes abrasive waterjet cutting services from Hydro-Lazer stand out is their commitment to accuracy. Custom CAD or DXF files are used to guide the machine, ensuring that each cut is executed with precision down to the micrometer. Whether the need is for custom parts, cut materials, or intricate shapes, this cutting process delivers results that other methods can’t match in terms of speed and precision.

Benefits of Abrasive Waterjet Cutting vs. Other Cutting Methods

When comparing abrasive waterjet cutting to traditional laser cutting, several benefits become apparent:

- No Heat-Affected Zones: Unlike laser cutting, which can warp materials due to heat, abrasive waterjet cutting services avoid this issue entirely. Since the process uses water and abrasives instead of heat, the cut material retains its original properties.

- Versatility: The technology is suitable for a wide range of materials, including sheet metal, custom parts, ceramics, glass, and more. This versatility makes it the preferred method for industries ranging from aerospace to automotive to industrial manufacturing.

- Precision and Accuracy: Hydro-Lazer’s waterjet cutting service guarantees precision, even with highly intricate designs. The ability to cut complex parts without the need for secondary finishing saves time and cost in production runs.

- Cost-Effective: Because the cutting process is faster and more efficient, it reduces material waste and the need for secondary processes. This efficiency results in cost-effective cutting solutions that are a long-term investment.

Materials That Can Be Cut with Abrasive Waterjet Technology

The beauty of abrasive waterjet cutting services lies in their ability to cut through a broad range of materials. Some of the materials Hydro-Lazer excels at cutting include:

- Metals: From soft metals like aluminum to hard metals like titanium, Hydro-Lazer’s waterjet cutting technology delivers precise, clean cuts for sheet metal and custom parts.

- Composites: Composite materials, which are sensitive to heat, benefit significantly from waterjet cutting as it preserves their structural integrity.

- Stone and Glass: Abrasive waterjet cutting is perfect for precision cutting of stone, marble, granite, and glass, which are difficult to cut using traditional methods.

- Plastics and Rubber: It’s also an excellent solution for cutting softer materials like plastics and rubber, where heat distortion could otherwise compromise their quality.

Industries That Benefit from Abrasive Waterjet Cutting

Hydro-Lazer’s abrasive waterjet cutting services are employed across a wide range of industries, including:

- Aerospace: Precise cuts are essential in the aerospace industry, where components must meet strict tolerances. Hydro-Lazer’s service delivers the necessary accuracy.

- Automotive: For high-performance vehicles, abrasive waterjet cutting ensures that all parts are made with the utmost precision and durability.

Manufacturing: From production runs to prototyping, Hydro-Lazer’s cutting solutions streamline the process, reducing time-to-market and waste. - Construction and Architecture: Whether it’s cutting custom parts for decorative elements or structural components, waterjet cutting delivers clean, intricate cuts that other methods can’t achieve.

Why Choose Hydro-Lazer for Abrasive Waterjet Cutting Services?

Hydro-Lazer is a standout leader in the field of abrasive waterjet cutting services, and here’s why:

- Unmatched Precision: Hydro-Lazer offers unparalleled precision for custom parts and cut materials that meet stringent industry standards.

- Versatility in Applications: Whether it’s a simple sheet metal cut part or a complex, multi-material component, Hydro-Lazer can handle any job with ease.

- Cost-Efficiency: With faster turnaround times and minimal material waste, Hydro-Lazer offers some of the most cost-effective cutting processes available today.

- Proven Expertise: With years of experience in waterjet cutting, Hydro-Lazer has built a reputation as a trusted partner for businesses looking for the highest quality in precision cutting.

Why Abrasive Waterjet Cutting is the Future of Precision

Abrasive waterjet cutting services represent the future of high-precision, versatile, and cost-effective cutting. Whether you’re looking to cut sheet metal, custom parts, or more intricate materials, Hydro-Lazer’s state-of-the-art technology ensures that every project is completed with exacting standards. For businesses seeking an edge in their production processes, abrasive waterjet cutting offers unmatched precision and efficiency.

A study by the International Journal of Advanced Manufacturing Technology found that waterjet cutting can achieve tolerances as tight as ±0.005 inches, offering a level of precision that far surpasses many traditional cutting methods.

As manufacturing processes evolve, industries are increasingly turning to abrasive waterjet cutting services for its ability to handle a diverse range of materials while maintaining high accuracy. The method’s flexibility in cutting complex parts, coupled with the absence of heat-affected zones, gives it a distinct advantage over traditional methods.

For businesses in need of precision cutting, we highly recommend considering abrasive waterjet cutting for its versatility, speed, and cost-efficiency. Hydro-Lazer’s services offer cutting-edge solutions for industries ranging from aerospace to construction. Explore Hydro-Lazer’s offerings and take your production to the next level with their expert abrasive waterjet cutting services.