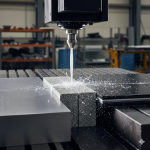

Manufacturers across Pennsylvania face the challenge of combining precision with efficiency on every project. Meeting tight specifications while keeping production timelines on track requires advanced cutting solutions that are both reliable and versatile. Hydro-Lazer’s water jet cutting service delivers fast, accurate results tailored to the unique needs of local businesses.

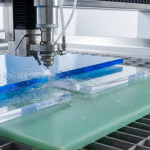

This technology handles a wide variety of materials, from metals and composites to plastics and ceramics, without compromising quality. Its precision eliminates the need for secondary finishing and reduces waste, keeping projects on schedule and within budget. Businesses can rely on consistent, high-quality results that meet even the most demanding design requirements.

Working with a trusted local partner ensures smooth communication, faster turnaround, and responsive support throughout the production process. Hydro-Lazer combines state-of-the-art water jet technology with hands-on expertise to streamline workflows and maximize productivity. Pennsylvania manufacturers gain a dependable solution that balances speed, accuracy, and flexibility for every custom cutting project.

What Water Jet Cutting Service Delivers for Your Pennsylvania Business

Hydro-Lazer offers water jet cutting services that combine versatility, precision, and material integrity, supporting a wide range of Pennsylvania projects.

Material Versatility

The service can handle metals such as aluminum, stainless steel, and titanium as well as stone, ceramic, and slate. Changing materials does not require new tooling, which allows Pennsylvania businesses to work efficiently across different projects. Metal fabrication shops can produce various components in a single day, improving workflow and project flexibility.

Precision Capabilities

Water jet cutting provides high tolerance accuracy down to +/- 0.005 inches and can accommodate complex geometries. CNC-controlled precision ensures clean edges and consistent results, reducing finishing time for Pennsylvania businesses. Components maintain their integrity for machine parts, architectural designs, and prototype projects, delivering reliable performance for each application.

No-Heat Advantage

The cold cutting process eliminates heat-affected zones and prevents material distortion. Sensitive metals and materials retain their strength and properties, making water jet cutting ideal for critical applications. It offers a practical solution for projects requiring high-quality cuts and preserved material performance.

Fast Turnaround Meets Exacting Precision

Speed

Water jet cutting provides rapid production for custom and small-batch projects. Transitioning between different materials is seamless, allowing manufacturing facilities to maintain continuity and meet deadlines. Fast water jet cutting service keeps operations smooth and ensures that projects move forward efficiently.

Precision

Water jet cutting delivers consistent, repeatable results for intricate patterns and multi-piece projects. Computer-controlled cutting minimizes human error, reduces material waste, and ensures accurate parts for production or design applications. Whether for machine components or architectural elements, Pennsylvania businesses benefit from reliable, precise cuts.

How Pennsylvania Businesses Use Water Jet Cutting Services

Manufacturing and Fabrication Shops

A metal fabrication shop in Pennsylvania receives an order for a custom machine component. Water jet cutting enables precise stainless steel and aluminum cuts for prototypes and small production runs. This approach allows shops to complete specialty work efficiently and produce components that meet strict tolerances without additional equipment investment.

Architectural and Design Applications

Contractors in Pennsylvania rely on water jet cutting for creating stone, ceramic, and slate patterns in commercial and residential spaces. Intricate inlays and geometric designs fit perfectly, supporting installation efficiency and high-quality outcomes. Water jet cutting provides a single-source solution that maintains design integrity and reduces coordination challenges.

Industrial Maintenance and Custom Components

Industrial facilities across Pennsylvania require custom parts for repairs and production line updates. Water jet cutting produces components such as brackets, gaskets, and specialized fixtures quickly, keeping operations on schedule. Fast and precise cutting helps facilities maintain productivity and respond effectively to project demands.

Why Pennsylvania Businesses Choose Local Water Jet Cutting Services

Partnering with a local provider like Hydro-Lazer in Freeport, PA, brings significant advantages for regional businesses. Projects move efficiently with reduced transit times and lower shipping costs, while direct communication with the team ensures precise execution and clarity at every stage. Local expertise in Pennsylvania manufacturing allows solutions that align with industry standards and practical operational needs.

Businesses benefit from Hydro-Lazer’s deep understanding of the Pittsburgh region and Western Pennsylvania manufacturing environment. This familiarity enables tailored services that streamline production, minimize delays, and maintain high-quality results for a variety of cutting projects. Teams can rely on hands-on support that anticipates challenges and delivers consistent performance across each assignment.

Long-term collaboration becomes seamless with Hydro-Lazer’s commitment to responsiveness and reliability. Ongoing water jet cutting requirements are met with adaptable solutions and attentive customer care, fostering trust and efficiency. By working with a local partner, Pennsylvania businesses gain both technical expertise and a dependable ally for continued growth and operational success.

Get Started with Your Pennsylvania Water Jet Cutting Project

Discover the possibilities with Hydro-Lazer in Freeport, PA. Every project receives careful attention, combining advanced water jet technology with local expertise. Your designs and industrial needs can come to life with precision, speed, and reliable service.

Each job is handled efficiently, ensuring timelines are met without compromising quality. The team provides tailored solutions for manufacturing, design, and other specialized applications. Working locally means every project benefits from hands-on support and quick communication.

Start your water jet cutting project today and experience a smooth, professional process. Hydro-Lazer makes it simple to request a quote or explore custom cutting options. Engage with experts who prioritize accuracy, speed, and the success of your project.