Delicate surfaces like glazed ceramic and porcelain tiles demand careful handling, as even a small misstep can lead to cracking or chipping. Imported or high-value tiles, such as those for shower niches or feature walls, require precision to maintain their integrity and aesthetic appeal. Traditional cutting methods can put these materials at risk, creating challenges for contractors and designers alike.

Waterjet cutting technology offers a solution by delivering accurate, clean cuts without compromising the tile’s surface. Complex shapes, curves, and patterns can be executed with confidence, preserving every piece while achieving precise alignment. Hydro-Lazer’s services ensure that intricate tile designs are handled seamlessly, maintaining both quality and detail across each project.

This precision enhances workflow, minimizes material loss, and supports timely project completion. Designers, contractors, and commercial specialists can confidently realize custom layouts and detailed patterns, knowing that each tile will fit perfectly. Waterjet cutting empowers creative possibilities while safeguarding both the investment in materials and the satisfaction of clients.

Understanding Ceramic Tile Behavior

Glaze Layer Sensitivity

Ceramic tile glazes are glass-like surfaces fused to clay bodies. Standard cutting methods create micro-fractures along the glaze, which may develop into chips during installation. Waterjet cutting applies controlled, precise erosion to maintain intact surfaces and clean edges. Tiles retain their finished look right to the perimeter.

Internal Stress Management

Ceramic and porcelain tiles have inherent stresses from the firing process. Traditional mechanical cuts can trigger these stresses, causing unpredictable fractures. Waterjet cutting applies no mechanical force, protecting the tile body while achieving precise dimensions for any application.

Complex Shape Precision

Curved edges, tight radii, and intricate patterns are challenging with conventional tools. Snap cutters handle straight lines, while circle cutters and grinders produce dust and uneven edges. Ceramic flooring waterjet cutting executes complex shapes with smooth, accurate results, allowing contractors to complete design-driven projects efficiently.

How Waterjet Cutting Enhances Tile Projects

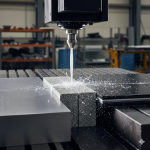

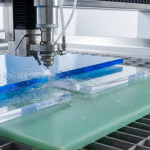

Stress-Free Cutting

A high-pressure water stream with fine abrasive particles removes material without vibration or force. Glazed surfaces stay pristine, and internal tile stresses remain undisturbed. Tiles separate cleanly along precise lines, making the process suitable for delicate and high-value materials.

Gradual Material Removal

Waterjet cutting progresses along programmed paths with measured erosion. Edges remain flawless, and intricate details are captured without risking micro-fractures. Complex shapes can be achieved without extra handling or adjustments.

Design Versatility

Digital patterns translate directly into cutting paths. Curves, radii, geometric designs, logos, and decorative borders are executed consistently across multiple tiles. This allows creative freedom for contractors while maintaining production efficiency.

Practical Applications for Custom Ceramic Patterns

Shower Niches and Alcove Trim

Custom pieces for shower niches, shelves, and recessed spaces can be cut to exact dimensions. Curved edges and angled sides are created with precision. Tiles fit seamlessly, reducing time spent on adjustments during installation.

Decorative Backsplash Inserts

Kitchen and bath backsplashes gain character through unique shapes and patterns. Waterjet cutting ensures each tile insert aligns with design requirements without compromising surface integrity, enabling elegant visual appeal for any installation.

Radius Cuts for Curved Walls and Columns

Curved walls, rounded columns, and architectural features demand precise tile shapes. Waterjet technology produces smooth radius cuts that follow contours accurately, enhancing workflow efficiency and minimizing material handling.

Diagonal Pattern Field Cuts

Diagonal layouts require multiple angled cuts for perimeter tiles. Waterjet cutting creates all necessary pieces with accuracy, delivering ready-to-install tiles that match design specifications and fit perfectly in their intended spaces.

Custom Floor Medallions and Feature Patterns

Tile medallions with geometric shapes or logos can be cut from standard tiles, producing intricate floor features. Waterjet cutting ensures consistency across multiple pieces, providing seamless alignment for unique flooring installations.

Precision Outlet and Fixture Cutouts

Electrical and plumbing fixture openings demand clean edges and exact sizing. Waterjet cutting produces accurate rectangular or circular cutouts without compromising tile edges, supporting professional and polished results.

Material Efficiency and Project Value

Waterjet cutting enhances material efficiency by enabling precise, accurate cuts on the first attempt. Complex patterns and delicate tiles can be shaped with confidence, reducing the need for rework and preserving valuable resources.

Contractors benefit from smoother project workflows, as components arrive ready for seamless installation. This precision supports consistent results and keeps projects on schedule, creating a sense of reliability throughout the process.

Conserving materials contributes to both practical and financial advantages. By minimizing waste and optimizing resources, waterjet cutting helps maximize project value while supporting sustainable and thoughtful design practices.

Considerations for Tile Types

Waterjet cutting performs seamlessly on a variety of tile types, including both glazed and unglazed ceramic. Glazed tiles retain their smooth, polished surfaces, while unglazed tiles achieve clean, precise edges even in intricate shapes.

Porcelain tiles, known for their density and hardness, are cut with consistent accuracy, maintaining quality without added tool strain. Each material benefits from the technology’s precision, ensuring that designs are executed exactly as envisioned.

This versatility supports professional outcomes across diverse projects, giving designers and installers confidence in both the quality and reliability of each piece. Floors, medallions, and custom patterns achieve refined results, regardless of material choice.

From Design to Installation

Each custom pattern starts with a digital design that directs precise waterjet cutting, producing tiles that match the intended shape and detail. This consistency enables efficient production of multiple pieces for larger projects.

Tiles arrive installation-ready, making assembly straightforward and accurate for contractors. Minimal adjustments are required, allowing projects to proceed smoothly and on schedule.

The process from initial design to finished floor ensures that every detail is maintained while maximizing efficiency, resulting in cohesive, high-quality flooring that meets both aesthetic and functional goals.

Enhancing Projects with Hydro-Lazer

Using Hydro-Lazer waterjet cutting, contractors can execute ceramic flooring projects with unmatched precision and efficiency. From shower niches to backsplashes, floor medallions, and detailed patterns, the technology produces accurate shapes, clean edges, and reduced material waste, ensuring successful installations.

Hydro-Lazer supports contractors in expanding their project capabilities while maintaining professional-grade quality. For custom tile cutting, this service offers a smooth workflow from design concept to final installation. Upgrade Your Ceramic Flooring — Start Your Custom Waterjet Project Now!