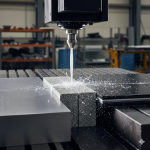

When 6-inch thick steel meets intricate geometries, when titanium demands flawless precision, when conventional cutting tools buckle under pressure—Hydro-Lazer’s water jet cutting service steps in. This is not about standard sheet metal trimming or light fabrication. This is about conquering materials so thick, dense, and complex that other methods simply fail.

For industries where performance is measured in inches of thickness, tons of weight, and microscopic tolerances, Hydro-Lazer brings extreme capability and confidence.

Ultra-Thick Material Mastery

Hydro-Lazer’s water jet cutting service has been battle-tested in heavy industry environments where traditional methods can’t keep up. The ability to cut through 12+ inches of steel, titanium, or superalloys while maintaining edge precision is not just a claim—it’s proven performance.

- Ultra-Thick Metals: From structural steel to titanium blocks, Hydro-Lazer maintains accuracy even through dense, unforgiving materials.

- Structural and Plate Materials: Heavy equipment components, shipbuilding plates, and bridge structures require power and consistency, and that’s exactly what this service delivers.

- Composite and Layered Systems: Thick fiber-reinforced composites, honeycomb structures, and ballistic armor are cut with precision, no matter how layered or complex.

- Specialty Thicknesses: Ceramic, refractory, heavy-duty rubber, and stone—all conquered with the same confidence.

Where thickness used to be a limitation, Hydro-Lazer turns it into another opportunity to prove industrial power.

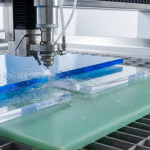

Complex Shape Cutting at Industrial Scale

Cutting through thick material is one challenge. Shaping it into intricate, production-ready forms is another. Hydro-Lazer’s water jet cutting service delivers precision geometries that rival fine machining—even in materials others consider uncuttable.

- Three-Dimensional Contours: Beveled edges, angled cuts, and complex curves are executed flawlessly.

- Internal Complexities: Deep internal pockets, slots, and undercuts are possible without damaging material integrity.

- Large-Scale Assemblies: Heavy machinery parts and multi-component structures are cut to fit seamlessly.

- Precision Features: From tight-tolerance holes to mechanical threads, Hydro-Lazer integrates detail with power.

This combination of brute force and fine detail sets Hydro-Lazer apart in industrial fabrication.

The Power Behind the Cut

Hydro-Lazer’s dominance comes from investing in extreme performance technology:

- Ultra-High Pressure Systems: 90,000+ PSI ensures cuts through even the thickest, hardest materials.

- Heavy-Duty Abrasive Delivery: Optimized flow keeps performance consistent under extreme loads.

- Precision Motion Control: Advanced motion systems maintain accuracy, regardless of material thickness.

- Industrial-Grade Infrastructure: Built for heavy-duty processing with large-format tables and robust safety systems.

Hydro-Lazer’s water jet cutting service doesn’t just meet industrial demands—it redefines them.

Industry Applications: Where the Impossible Becomes Standard

Hydro-Lazer powers critical industries where failure is not an option:

- Heavy Manufacturing & Fabrication: Mining, oil and gas, and power generation equipment.

- Defense & Aerospace: Ballistic armor, aerospace structures, and defense vehicle components.

- Marine & Offshore: Shipbuilding, marine propulsion, and offshore platform parts.

- Energy & Utilities: Power plants, renewable energy systems, and nuclear infrastructure.

When industries demand reliability under the harshest conditions, Hydro-Lazer answers with unmatched cutting power.

Performance Under Pressure

Hydro-Lazer’s reputation is built on one truth: performance under extreme conditions.

- Challenge Management: Taking on projects others cannot complete.

- Production Scale: Delivering consistency from prototypes to mass production.

- Quality Assurance: Precision maintained regardless of thickness or complexity.

- Reliability: A proven partner for safety-critical, mission-critical components.

Hydro-Lazer’s water jet cutting service is more than capability—it’s a partnership for industrial strength and long-term reliability.

Hydro-Lazer: Your Heavy-Duty Cutting Solution

In a world where extreme materials demand extreme solutions, Hydro-Lazer stands as the trusted powerhouse. Every project begins with a capability consultation, followed by application of cutting-edge technology, and finishes with performance delivery that exceeds industrial expectations.

Whether you’re building infrastructure, fabricating heavy machinery, or engineering aerospace components, Hydro-Lazer’s water jet cutting service ensures that no material is too thick, no geometry too complex, and no challenge too extreme.

Hydro-Lazer isn’t just cutting material. It’s cutting through limits.