In the realm of glass cutting services, choosing the right technology can greatly impact the outcome of your project.

While diamond saws have been a long-standing option, waterjet technology is quickly becoming the go-to choice for those seeking precision and efficiency.

At Hydro-Lazer, we specialize in waterjet glass cutting services that offer unparalleled advantages for intricate glasswork.

Understanding Waterjet Glass Cutting Services

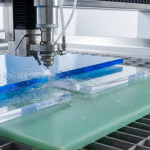

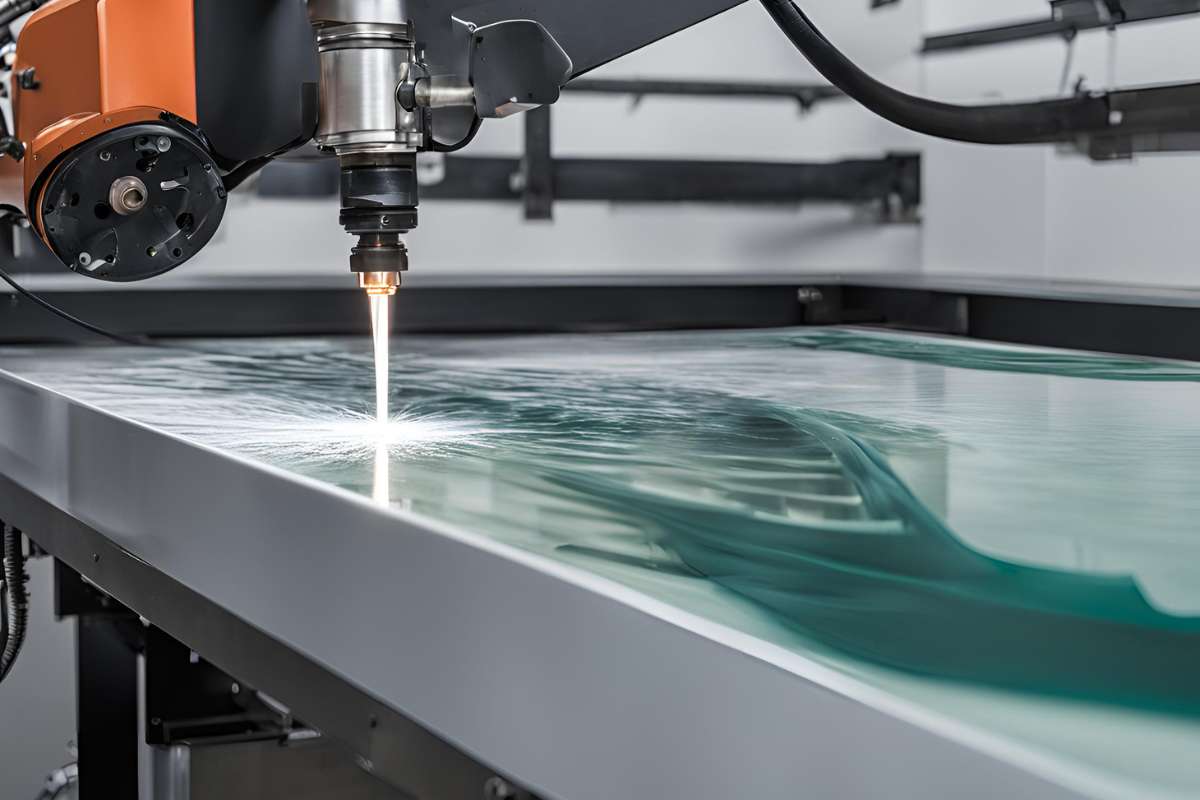

Waterjet cutting uses a high-pressure stream of water, often mixed with an abrasive substance, to slice through glass with exceptional precision. This process provides several benefits over traditional diamond saw methods, making it ideal for intricate designs.

Cut Quality and Precision

One of the standout benefits of waterjet glass cutting services is the superior cut quality.

Our waterjet systems at Hydro-Lazer can achieve exceptionally smooth edges without chipping or cracking, which is often a challenge with diamond saws.

The precision of waterjet cutting allows for complex shapes and patterns in order to create perfect decorative and architectural glasswork.

Minimizing Material Waste

Waterjet cutting is also known for its efficiency in material usage.

The process produces minimal kerf (cut width), reducing material waste compared to diamond saws, which often have a wider blade and therefore a larger kerf.

This efficiency can lead to cost savings and more effective use of materials for projects with expensive glass types.

Operational Safety and Environmental Impact

When it comes to safety, waterjet glass cutting services outshine diamond saws.

The waterjet process is non-thermal, meaning there is no heat generated, reducing the risk of burns or fires.

Additionally, it eliminates airborne dust and particles that can pose health risks in traditional cutting environments.

Environmentally, waterjet systems are more sustainable.

They use recyclable water and produce less hazardous waste, making them a greener choice than diamond saws, which often require lubrication oil and create more substantial waste.

Hydro-Lazer’s Glass Cutting Services

At Hydro-Lazer, we’ve embraced waterjet glass cutting as our specialty, ensuring that every project benefits from this advanced technology:

- Precision Technology: Our high-pressure systems can cut glass with extreme accuracy, maintaining tight tolerances needed for detailed designs.

- Versatile Applications: We handle a wide range of glass types, from standard to tempered, allowing for versatility in design possibilities.

- Expert Team: With over 30 years of experience, our team can assist with everything from design consultation to final production.

- Custom Solutions: Whether you need intricate patterns or large-scale glass installations, we tailor our services to meet your unique specifications.

Ideal Applications for Waterjet Glass Cutting Services

These are some of the top applications where waterjet excels:

- Decorative Glasswork: Intricate designs for home decor or corporate interiors.

- Architectural Installations: Precision-cut glass for facades and unique building features.

- Automotive Glass: Customized shapes for windshields or unique vehicle designs.

- Art Projects: Helping artists realize their visions with precise cuts and unique patterns.

Case Studies

Consider a few examples of how our waterjet glass cutting services have transformed projects:

- Interior Design: We assisted an interior design firm by creating intricate patterned glass panels for a modern office space. The precision of our waterjet cutting allowed for detailed motifs that added a sophisticated touch to the environment.

- Public Art Installation: A renowned artist collaborated with us to produce a large-scale glass sculpture for a public park. The smooth edges and precise angles achieved through waterjet technology were essential in bringing the artist’s vision to life without the stress fractures that can occur with diamond saws.

The Increasing Preference for Waterjet in Glass Cutting

As more industries recognize the advantages of waterjet glass cutting services, we see a growing preference for this technology over traditional methods.

Its ability to combine safety, quality, and environmental responsibility makes it an attractive option for various applications.

At Hydro-Lazer, we’re committed to staying at the forefront of this technology, continually improving our equipment and techniques to offer the best possible service to our clients.

Are you ready to explore the advantages of waterjet glass cutting services for your next project?

Contact us today to discuss how our precision cutting can elevate your glasswork.

Let’s create something extraordinary together, breaking new ground with smart technology that benefits both your project and the planet.